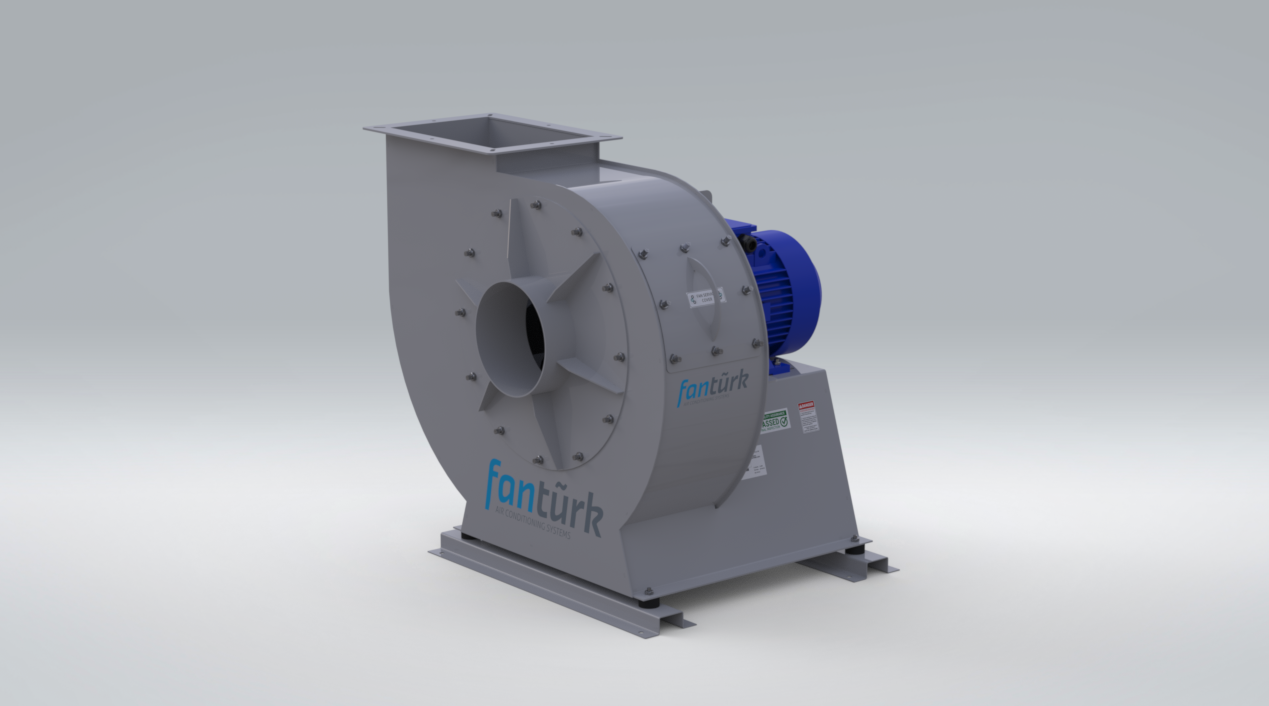

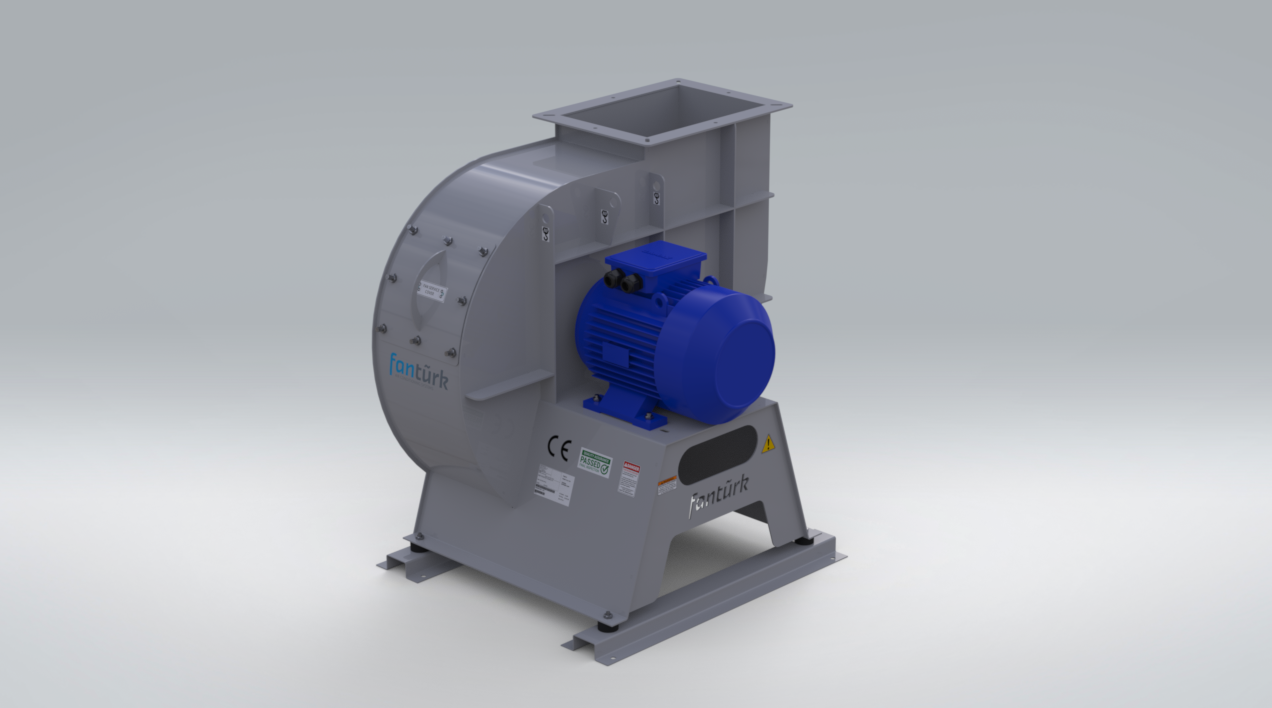

OBF Medium Pressure Snail Fan, in other words, OBF series are single suction high efficiency volute fans. The maximum temperature of the fluid being sucked should be 120°C. Some modifications are required in the manufacture of the fan for higher temperature operation. The body is made of S235 steel and all surfaces are coated with epoxy paint resistant to corrosion. Can be made of stainless steel for corrosive and high temperature environments. The fan drive can be selected as a belt-driven, direct-coupled or coupling system. Optionally, it can be manufactured with Ex-Proof feature. It is suitable for use in dusty air suctions, ventilation, drying, mechanical extraction, dust, sawdust or toxic gas systems in all kinds of ventilation systems.

As it is known, Snail Fans, which are used as an indispensable device of ventilation systems, are the most suitable devices to meet the ventilation need in systems with high flow rates and high pressure loss at the same time. It is heavily preferred in heating, cooling systems, dust, sawdust suction lines, ambient ventilation and industrial applications. Snail Fans, produced with Fantürk quality, are selected among various models, the most suitable for the desired operating point in the systems.

Moreover, these fans provide a very efficient operation due to the snail form in their case structure. This form has a positive effect on efficiency, energy saving and desired flow values in the operating device. This is the reason why especially volute fans are chosen in heavy industry and industrial applications. As Fantürk, in addition to choosing the most suitable snail fan to work at the working points requested by our customers from our standard models, special designs can be made and produced for special applications.

The produced volute fans are produced in accordance with the maximum continuous operation at 120°C. This resistance can be increased to 200°C temperature ranges by taking different precautions in the volute body and motor drive type. In addition, production with Ex-Proof feature is possible upon request. Fanturk Snail Fans are produced with direct coupled drive as standard. However, a belt-pulley or coupling drive system can be applied in line with the customer’s request. The throw direction of the snail fans produced thanks to its ergonomic design can be adjusted as desired. Optional sliding system application can be made for these products upon request. In this system, necessary operations can be performed by placing a skid under the motor stand and removing the motor stand and rotor without interfering with the fan body during maintenance and cleaning.

OBF Medium Pressure Snail Fan Technical Specifications

OBF series are single suction high efficiency volute fans. The maximum temperature of the fluid being sucked should be 120°C. Some modifications are required in the manufacture of the fan for higher temperature operation. The body is made of S235 steel and all surfaces are coated with epoxy paint resistant to corrosion. Can be made of stainless steel for corrosive and high temperature environments. Fan drive can be belt-sourced, directly coupled or coupled system.

Optionally, it can be manufactured with Ex-Proof feature. Areas of Usage It is suitable to be used in dusty air intakes, ventilation, drying, mechanical extraction, dust, sawdust or toxic gas systems in all kinds of ventilation systems. The snail fan throw position must be specified when ordering. In order to determine the firing position, the ideal product model is selected when looking from the engine side.

OBF Medium Pressure Snail Fan Models

OBF 100/0,18 Model

- Voltage 380 V

- Frequency 50 Hz

- Power 0,18 kW

- Cycle 2820 d/d

- Noise Level 62 dBA

- Weight 19 kg

OBF 140/0,37 Model

- Voltage 380 V

- Frequency 50 Hz

- Power 0,37 kW

- Cycle 2800 d/d

- Noise Level 65 dBA

- Weight 27 kg

OBF 160/0,55 Model

- Voltage 380 V

- Frequency 50 Hz

- Power 0,55 kW

- Cycle 2780 d/d

- Noise Level 68 dBA

- Weight 31 kg

OBF 180/1,1 Model

- Voltage 380 V

- Frequency 50 Hz

- Power 1,1 kW

- Cycle 2900 d/d

- Noise Level 72 dBA

- Weight 46 kg

OBF 200/2,2 Model

- Voltage 380 V

- Frequency 50 Hz

- Power 2,2 kW

- Cycle 2900 d/d

- Noise Level 73 dBA

- Weight 62 kg

OBF 224/4 Model

- Voltage 380 V

- Frequency 50 Hz

- Power 4 kW

- Cycle 2910 d/d

- Noise Level 77 dBA

- Weight 79 kg

OBF 250/7,5 Model

- Voltage 380 V

- Frequency 50 Hz

- Power 7,5 kW

- Cycle 2910 d/d

- Noise Level 82 dBA

- Weight 115 kg

OBF 280/11 Model

- Voltage 380 V

- Frequency 50 Hz

- Power 11 kW

- Cycle 2945 d/d

- Noise Level 62 dBA

- Weight 166 kg

OBF 315/18,5 Model

- Voltage 380 V

- Frequency 50 Hz

- Power 18,5 kW

- Cycle 2930 d/d

- Noise Level 87 dBA

- Weight 211 kg

About Fanturk

Our company has been operating in Bursa under the name of Havart Klima Ltd Şti and the brand name of Fantürk since 2002. In an area of 7000 m², it addresses the sector with the production of air conditioning devices, automation system software and MCC-DDC panel manufacturing with our engineers and blue-collar employees who are experts in their branches.

Fantürk is a company that produces technologies that give humanity a breather, aims to be a worldwide leader company and tries to offer innovative technologies for the benefit of humanity. In the light of our experience, our company, which is sensitive to customer expectations, prioritizes quality, and adopts respect for business ethics and ethical beliefs, has a vision that aims to develop and grow. Our principle is to have a discipline that is sensitive to customer expectations, attaches importance to quality, and respects ethical values.

In the light of our experience and knowledge, our company, which is sensitive to customer expectations, prioritizes quality, and adopts respect for business ethics and ethical beliefs, has a vision that aims to develop and grow. Attaching importance to R&D studies, Fantürk aims to increase its production and service quality based on international standards. Our main goal is to be a worldwide leader organization that produces technologies that breathe for all humanity by offering innovative technologies for the benefit of humanity.

Our Service and Product Categories

Duct Type Fans, Roof Type Fans, Heat Recovery, Parking Lot Ventilation, Stair and Elevator Pressurization, Snail Fan, Cell Fans, Air Handling Unit, Dust Collection System, Hot Air Appliance

Our products

- Y-KTF Round Duct Type Fan

- D-KTF Rectangular Duct Type Fan with External Motor

- SHS Duct Type Shelter Ventilation Device

- ÇTF (230V) Single Phase Roof Type Radial Fan

- ÇTF (380V) Three Phase Horizontal Discharge Roof Type Radial Fan

- ÇTF (380V) Three Phase Vertical Discharge Roof Type Radial Fan

- Ç-FWA Roof Type Axial Fan

- IGK Ceiling Type Heat Recovery Device

- J-FWA Axial Jet Fan

- R-FWA Radial Jet Fan

- Y-FWA Axial Smoke Exhaust Fan

- P-FWA Axial Fresh Air Fan

- Car Park Ventilation System Automation Panel

- Pressurization System Automation Panel

- ABF Low Pressure Snail Fan

- OBF Medium Pressure Snail Fan

- ECO Series Forward Curved Closed Blade Cell Fan

- M-HA Metal Oil Filter Cell Kitchen Aspirator

- H-FWA Cell Axial Fans

- FKS Air Handling Unit

- HNS Pool Dehumidification Unit

- TT Dust Collection System

- R-APA Radial Fan Hot Air Appliance

- A-APA Axial Fan Hot Air Appliance

- FRTT Rooftop Roof Type Air Handling Unit

- T-FWA Tunnel Jet Fan

OBF series are single suction high efficiency and low noise fans. The maximum temperature of the suction fluid should be 120 ° C. In order to work at a higher temperature, modifications to the fan manufacturing are required. Made of high quality corrosion resistant S355 steel and coated with epoxy paint. Can be made of stainless steel for corrosive and high temperature environments. Fans are radial fans with backward curved blades. It is possible to drive the fan with belt pulley, direct coupling or elastic coupling. Optionally, it can be manufactured with ExProof feature.

Usage Areas

It is suitable for use in dusty air suction, ventilation, drying, mechanical extraction, dust, sawdust or any kind of ventilation systems with toxic gas systems