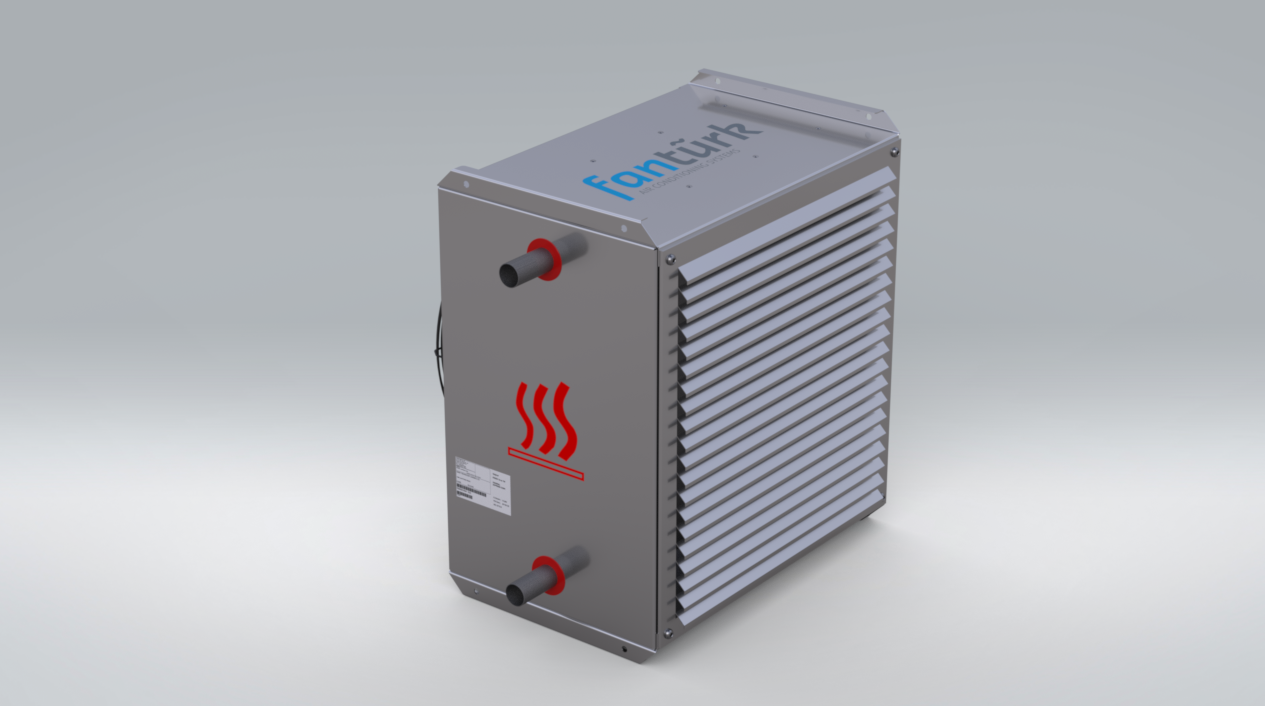

A-APA Axial Fan Hot Air Apparatus; A-APA Axial Fan Hot Air Appliances are the most suitable devices for heating systems in large volumes. It is mounted on a construction that is attached to the wall for assembly. A-APA axial appliances have high performance and trouble-free operation. It is produced in capacities of 4.100 – 24.200 kcal/h under hot water working conditions of 90 / 70 °C as standard. If desired, production can be made with hot water and steam according to working conditions. The body is made of high quality galvanized steel resistant to corrosion. Self-powered, high-efficiency aluminum (optional plastic) propeller fan is used for air blowing. The heater coil is manufactured with copper tube and aluminum fins. It is manufactured as standard (230 V -50 Hz) or suitable for use in other voltages and frequencies upon request. Class F, S1, IP55 motor is used. It is suitable for use in closed areas, warehouses, hangars, workshops, sports halls, garages, production facilities, whose ceiling height exceeds 4 m.

Hot air apparatus consists of body, heater coil (coil), fan & motor group and air adjustment louver. The main advantages of the hot air appliance are; It is economical, has small volumes compared to high heating capacities, and is user-friendly. By using the water you will draw from the heating system in your building, the hot water in your business or the steam obtained from the steam boiler, you will provide the most economical heating method in a practical way. In addition, there is no need for assembly processes that require expertise, expert personnel and special installation materials. Since the hot air appliance works according to the principle of free discharge and free suction, it is not suitable for duct connection.

In the selection and placement of the hot air appliance, attention should be paid to the homogeneous heating of the space, the blowing of the air in accordance with the working level of the people and the absence of disturbing air currents. In order to ensure homogeneous heat distribution in the space, the number of devices must be calculated correctly. As a general acceptance, each device should have a heating capacity of 8000~16000 kcal/h. The heat power of the hot air appliance depends on the difference between the heating fluid and the air passing through the coil and the air velocity. The higher the air velocity and temperature difference, the higher the heat output of the device. It can reach up to 35000 kcal/h with 90/70 °C hot water in axial fan hot air appliance types and 48000 kcal/h with 90/70 °C hot water in radial fan hot air appliance types.

A-APA Axial Fan Hot Air Appliance Components

Body

The body part of the hot air appliance is manufactured from galvanized sheet of appropriate thickness. Then the interior and exterior surfaces are painted with electrostatic oven paint against corrosion.

Heating Coil Serpentine

Two or three rows of copper pipes and aluminum fins, suitable for the heating capacity of the hot air appliance, are used. Standard copper pipe is used for 90/70 °C hot water usage, and thick-walled copper tube serpentine is used for 110/80 °C superheated water and 3 ATU steam usage. In case of using 6 Atu steam, a specially designed thick-walled copper tube serpentine is used by increasing the wall thickness even more. Heating fluid inlet and outlet connections are threaded as standard. It is manufactured as flanged for steam systems.

Fan ve Motor

Two types of fans, radial and axial, are used in the hot air apparatus. In general, if the height of the place where the devices will be operated is less than 3-4 meters, it is recommended to use an axial fan, and in higher volumes, a radial fan hot air appliance should be used. In some series, statically and dynamically balanced, vibration-free, infrequent bladed radial fans are used inside the hot air apparatus. The blowing distances are large; because the radial fan used compresses the air drawn from the environment between its blades and throws it forward rapidly. The silent and safe fan is directly connected to the motor and works with 230 V/50 Hz mains current. In the appropriate series, static and dynamically balanced, vibration-free and silent axial fans connected directly to the motor are used inside the hot air apparatus. Safety is provided by a protection cage. It works with 230 V/50 Hz mains current.

Air Adjustment Louver

The louvers on the blowing side of the hot air appliance can be adjusted to direct the blowing air into the space as desired. It is functional and decorative. It is made of special aluminum extruded profile and anodized coated. Axial hot air appliance can be mounted on the wall with optional suspension feet. Standard holes are drilled on the hanger legs, which are manufactured to carry the weight of the hot air appliance, making it easier to mount on the wall. With the optional wall-mounted mechanical room thermostat, the desired temperature in the room is adjusted. When the set temperature is reached, the hot air appliance fan stops, when the temperature drops, the fan starts again.

About Fantürk

Our company is a company that produces technologies that give humanity a breather, aims to be a world-leading organization and tries to offer innovative technologies for the benefit of humanity. In the light of our experience, our company, which is sensitive to customer expectations, prioritizes quality, and adopts respect for business ethics and ethical beliefs, has a vision that aims to develop and grow. Our principle is to have a discipline that is sensitive to customer expectations, attaches importance to quality, and respects ethical values.

Our company has been operating in Bursa under the name of Havart Air Conditioning Limited Company and the brand name of Fantürk since 2002. In an area of 7000 m², it addresses the sector with the manufacture of air conditioning devices, automation system software and MCC-DDC panel manufacturing with our engineers and blue-collar employees who are experts in their branches.

In the light of our experience and knowledge, our company has a vision that is sensitive to customer expectations, prioritizing quality, and respecting business ethics and ethical beliefs. Attaching importance to R&D studies, Fantürk aims to increase its production and service quality based on international standards. Our main goal is to be a worldwide leader organization that produces technologies that breathe for all humanity by offering innovative technologies for the benefit of humanity.

Our Service and Product Categories

Duct Type Fans, Roof Type Fans, Heat Recovery, Parking Lot Ventilation, Stair and Elevator Pressurization, Snail Fan, Cell Fans, Air Handling Unit, Dust Collection System, Hot Air Appliance

Our products

- Y-KTF Round Duct Type Fan

- D-KTF Rectangular Duct Type Fan with External Motor

- SHS Duct Type Shelter Ventilation Device

- ÇTF (230V) Single Phase Roof Type Radial Fan

- ÇTF (380V) Three Phase Horizontal Discharge Roof Type Radial Fan

- ÇTF (380V) Three Phase Vertical Discharge Roof Type Radial Fan

- Ç-FWA Roof Type Axial Fan

- IGK Ceiling Type Heat Recovery Device

- J-FWA Axial Jet Fan

- R-FWA Radial Jet Fan

- Y-FWA Axial Smoke Exhaust Fan

- P-FWA Axial Fresh Air Fan

- Car Park Ventilation System Automation Panel

- Pressurization System Automation Panel

- ABF Low Pressure Snail Fan

- OBF Medium Pressure Snail Fan

- ECO Series Forward Curved Closed Blade Cell Fan

- M-HA Metal Oil Filter Cell Kitchen Aspirator

- H-FWA Cell Axial Fans

- FKS Air Handling Unit

- HNS Pool Dehumidification Unit

- TT Dust Collection System

- R-APA Radial Fan Hot Air Appliance

- A-APA Axial Fan Hot Air Appliance

- FRTT Rooftop Roof Type Air Handling Unit

- T-FWA Tunnel Jet Fan

It is made of high quality corrosion resistant galvanized steel. A self-powered aluminum axial fan is used for air blowing. It can be produced optionally with a plastic propeller. The heater coil is manufactured with copper tube and aluminum fins.

As a standard, production is carried out in capacities of 4,100 – 24,200 kcal/h in 90°C/70°C hot water operating regime. It can be produced according to working conditions with hot water and steam upon request.

The A-APA series is the ideal choice for high performance and trouble-free operation.

Usage Areas

It can be used in closed areas, warehouses, hangars, workshops, sports halls, garages, production facilities, whose ceiling height exceeds 4m.