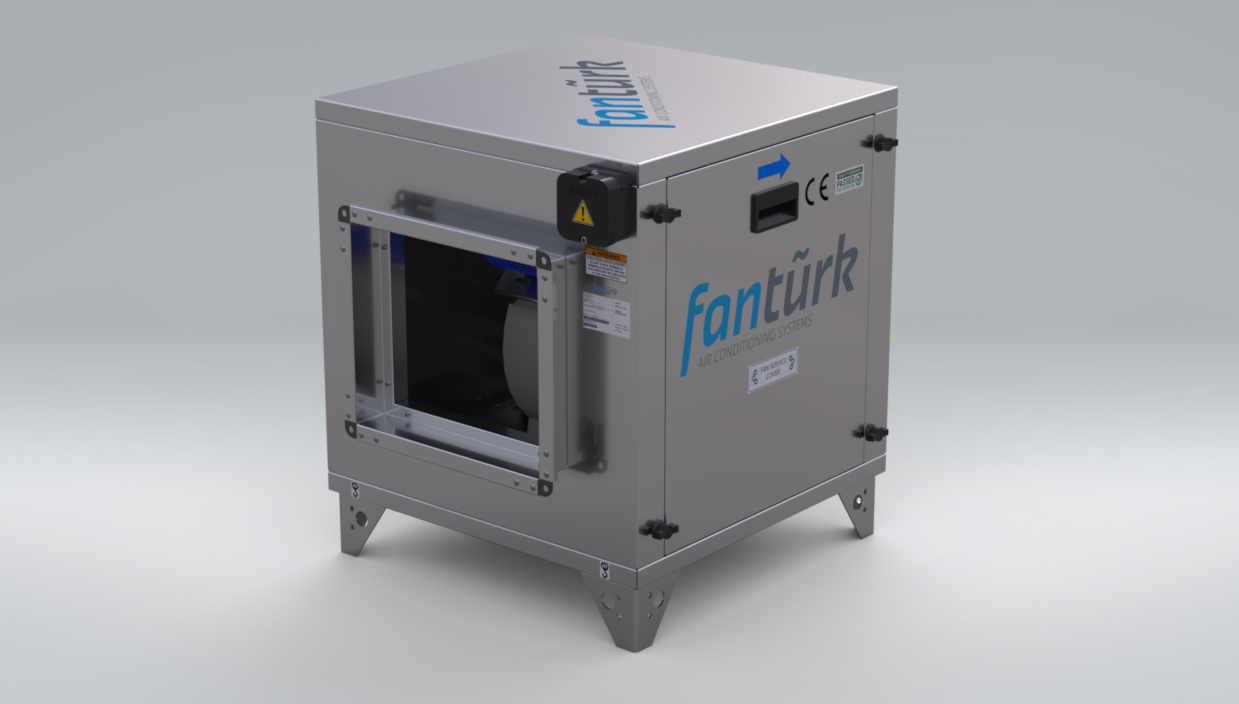

ECO Series Forward Curved Dense Bladed Cell Fan is manufactured from high quality corrosion resistant galvanized steel. The fans are belt-pulley driven and first of all, they are radial fans with curved blades. Thanks to the belt and pulley drive system, it is possible to manufacture the desired flow-pressure working pressure. The ECO series is the ideal choice for high performance and trouble-free operation. Mechanical ventilation systems are used when natural ventilation methods are insufficient or ventilation is desired by keeping the indoor temperature constant. Fresh air and exhaust systems are used in these systems.

Based on the energy source that activates the ventilation system, natural-mechanical ventilation and mechanical ventilation are used. Chimney aspirators working with the force of the wind can be given as an example of natural mechanical ventilation. Examples of mechanical ventilation are fans with inlet and mechanical outlet through natural ventilation, ventilators with inlet and natural outlet through mechanical ventilation, and ventilator and fan systems with inlet and outlet through mechanical ventilation.

Cell fans can be used as aspirators and ventilators in all kinds of residence, cafe, hospital, industry, office, kitchen and residential ventilation where compact solutions are needed. Cell fans are produced in 16 different models between 500 m³/h and 100,000 m³/h air flow rates. It is the most unique fan type in its class thanks to its insulated cabinet. Thanks to its wide selection range and modular system, assembly and disassembly processes are very easy. If desired, it can be produced in higher capacities according to the usage areas. For cell fan prices and more detailed product specifications, you can browse the products listed below or call our customer service for information.

Closed-bladed cell aspirators (fans) are high-efficiency, radial double-suction fans with forward curved blades, which are statically and dynamically balanced. They are used to evacuate the polluted air in the environment and place or to press fresh air. Dense bladed cell fans are frequently preferred in places where sound level is important, as they are in an insulated cabinet. Hotels, restaurants, hospitals, movie theaters, chemistry, textile industries, printing are just a few of the usage areas.

The bodies of the products are made of extruded aluminum profile carcass and plastic corner elements. Cabinet construction is combined with plastic corner elements of aluminum profiles. The panels on the surface of the cabinet are double skinned and have polyurethane insulation material between them. Nicotra fans with double suction, forward-curved or backward-curved propellers and belt pulleys are used in dense-bladed cell fans.

ECO Series Forward Curved Closed Blade Cell Fan Technical Specifications

ECO series cell fans are manufactured in high quality, fully sealed, with low or high suction and blowing capacity, depending on the nature of the ambient air to be used, to refresh the ambient air in places where heating and cooling is not desired. The body is made of high quality galvanized steel resistant to corrosion.

The inner surface is completely covered with 6mm rubber insulation. The fans used are double inlet radial fans with forward curved blades. The motor is mounted above the fan. Fan drive is belt welded system. In this way, the fan speed can be adjusted to meet the working conditions optimally. It is suitable for ventilation needs of workplaces, offices, cafeterias, markets, restaurants, meeting rooms, shopping centers, hospitals, industrial facilities.

ECO Series Forward Curved Dense Bladed Cell Fan Models

ECO-1 Model

- Flow 2500 m³/h

- Pressure 270 Pa

- Total Static Pressure 274 Pa

- Engine Power 0,75 Kw

- Engine Cycle 1370 d/d

- Weight 43 kg

ECO-2 Model

- Flow 3500 m³/h

- Pressure 400 Pa

- Total Static Pressure 406 Pa

- Engine Power 1,1 Kw

- Engine Cycle 1380 d/d

- Weight 48 kg

ECO-3 Model

- Flow 5000 m³/h

- Pressure 320 Pa

- Total Static Pressure 326 Pa

- Engine Power 1,5 Kw

- Engine Cycle 1385 d/d

- Weight 55 kg

ECO-4 Model

- Flow 7500 m³/h

- Pressure 300 Pa

- Total Static Pressure 306 Pa

- Engine Power 2,2 Kw

- Engine Cycle 1405 d/d

- Weight 65 kg

ECO-5 Model

- Flow 10000 m³/h

- Pressure 400 Pa

- Total Static Pressure 411 Pa

- Engine Power 3 Kw

- Engine Cycle 1405 d/d

- Weight 80 kg

ECO-6 Model

- Flow 12500 m³/h

- Pressure 345 Pa

- Total Static Pressure 355 Pa

- Engine Power 3 Kw

- Engine Cycle 1405 d/d

- Weight 170 kg

ECO-7 Model

- Flow 15000 m³/h

- Pressure 294 Pa

- Total Static Pressure 308 Pa

- Engine Power 4 Kw

- Engine Cycle 1425 d/d

- Weight 174 kg

ECO-8 Model

- Flow 17500 m³/h

- Pressure 380 Pa

- Total Static Pressure 400 Pa

- Engine Power 5,5 Kw

- Engine Cycle 1430 d/d

- Weight 185 kg

Fanturk Air Conditioning Systems

Our company has been operating in Bursa under the name of Havart Klima Ltd Şti and the brand name of Fantürk since 2002. In an area of 7000 m², it addresses the sector with the production of air conditioning devices, automation system software and MCC-DDC panel manufacturing with our engineers and blue-collar employees who are experts in their branches.

Fantürk is a company that produces technologies that give humanity a breather, aims to be a worldwide leader company and tries to offer innovative technologies for the benefit of humanity. In the light of our experience, our company, which is sensitive to customer expectations, prioritizes quality, and adopts respect for business ethics and ethical beliefs, has a vision that aims to develop and grow. Our principle is to have a discipline that is sensitive to customer expectations, attaches importance to quality, and respects ethical values.

In the light of our experience and knowledge, our company, which is sensitive to customer expectations, prioritizes quality, and adopts respect for business ethics and ethical beliefs, has a vision that aims to develop and grow. Attaching importance to R&D studies, Fantürk aims to increase its production and service quality based on international standards. Our main goal is to be a worldwide leader organization that produces technologies that breathe for all humanity by offering innovative technologies for the benefit of humanity

Our Service and Product Categories

Duct Type Fans, Roof Type Fans, Heat Recovery, Parking Lot Ventilation, Stair and Elevator Pressurization, Snail Fan, Cell Fans, Air Handling Unit, Dust Collection System, Hot Air Appliance

Our products

- Y-KTF Round Duct Type Fan

- D-KTF Rectangular Duct Type Fan with External Motor

- SHS Duct Type Shelter Ventilation Device

- ÇTF (230V) Single Phase Roof Type Radial Fan

- ÇTF (380V) Three Phase Horizontal Discharge Roof Type Radial Fan

- ÇTF (380V) Three Phase Vertical Discharge Roof Type Radial Fan

- Ç-FWA Roof Type Axial Fan

- IGK Ceiling Type Heat Recovery Device

- J-FWA Axial Jet Fan

- R-FWA Radial Jet Fan

- Y-FWA Axial Smoke Exhaust Fan

- P-FWA Axial Fresh Air Fan

- Car Park Ventilation System Automation Panel

- Pressurization System Automation Panel

- ABF Low Pressure Snail Fan

- OBF Medium Pressure Snail Fan

- ECO Series Forward Curved Closed Blade Cell Fan

- M-HA Metal Oil Filter Cell Kitchen Aspirator

- H-FWA Cell Axial Fans

- FKS Air Handling Unit

- HNS Pool Dehumidification Unit

- TT Dust Collection System

- R-APA Radial Fan Hot Air Appliance

- A-APA Axial Fan Hot Air Appliance

- FRTT Rooftop Roof Type Air Handling Unit

- T-FWA Tunnel Jet Fan

It is made of high quality corrosion resistant galvanized steel. The fans are belt-pulley driven and first of all they are radial fans with curved blades. Thanks to the belt pulley drive system, it is possible to manufacture the desired flow-pressure working pressure. The ECO series is the ideal choice for high performance and trouble-free operation.

Usage Areas

It can be used as aspirator and ventilator in all kinds of residence, cafe, hospital, industry, office, kitchen and residential ventilation where compact solutions are needed.