Pressurization System Automation Panel; Pressurization system is an important automation system product that ensures the correct flow and direction of the air in the facility. It is used for smoke evacuation and overpressure system in these products, which are especially used within the scope of fire fighting. While automation systems are beginning to spread rapidly today, systems such as life saving and escape facilitation have developed as well as facilitating human life. One of them is the systems defined as pressurization systems or fire escape pressurization automation. The basic principle of this system is generally based on the control of fresh air fans in stairwells or elevator shafts. Fire escape automation systems can be integrated into smart building systems as well as controlled separately. The pressurization process is generally carried out by the fan on the roof blowing air into the stairwell.

In accordance with the legislation, it is obligatory to install a fire escape pressurization system in all buildings that meet the following conditions:

- If the height of the stairwell is more than 30.50 m in all buildings, excluding residences.

- Escape stairs serving the basement in buildings with more than 4 basement floors.

- Residences with a building height of more than 51.50 m.

- Emergency elevator shafts.

Pressurization System Automation Panel

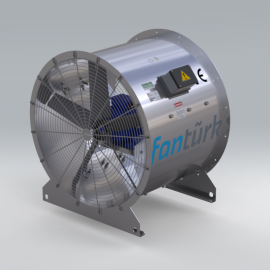

Pressurization Systems have different working principles and purposes. The most commonly used pressure fan system is the system that prevents smoke and fire entry into this area with the back pressure used in fire stairs and halls. Cell fans, axial cell fans, elevator pressurization fans and roof type axial fans are the main types of these products. The control of these fans is done with the help of sensors and software in the system. The fans are controlled via automation controllers and software, and it is ensured to act according to the information coming from the fire detection system or other weak current systems. Regulations on the usage area of the pressurization system have been prepared. Fan controllers and automation panels are installed to ensure the integration of these products into the automation system, especially in buildings that use fans. The pressurization fans and the automation panel that controls this system are very important in terms of ventilation traffic and direction in the building.

Existing system motors in pressurization systems are actuated by the inverter. An inverter is a type of power inverter. In other words, it is an electrical power converter that converts direct current to alternating current. The AC power generated at the inverter output can be of any voltage and frequency depending on the transformers, switching and control circuits used. After the fire signal comes from the fire panel to the ladder pressurization system automation panel, the inverter starts. The pressure in the stairwell is read by the pressure sensors located on the lower floor and in the middle of the building according to its size. According to the incoming pressure information, the inverter accelerates the motor and stabilizes its speed when it reaches 50 pascal pressure. The pressure in the stairwell should be a maximum of 50 pascals according to world standards. It is the most ideal pressure required for people to easily push the fire doors from the place where they are at the time of escape and to prevent smoke from entering the place where there is a fire at that moment. When the fan or fans work, it fills the stairwell like a balloon logic (the same pressure everywhere).

Fire escape pressurization systems are systems that need to be maintained at frequent intervals. Failure of the engine to run, no fire information, no pressure information can cause loss of life in a big fire. In the automation of stair pressurization fans, the stairwells are kept at constant positive pressure (50 Pa) to ensure that people escape from the emergency stairs in case of fire. Its importance in our panel and automation systems is better understood here. Branded, high quality and internationally certified products should be preferred. You can contact our company directly for the necessary technical details, product models and advantageous price offers.

Stair Pressurization Systems:

The purpose of pressurization is to prevent smoke from entering fire stairs and elevators, and to provide human evacuation in a smoke-free environment, and to provide firefighters with a suitable means of transportation for fire response. According to the regulation on fire protection of buildings, fire stairs must be pressurized if the height of the stairwell is more than 30.5 m in all buildings, excluding residences. In residences, this height is 51.50 m. When the pressurization system works, the difference between the stairwell and the building use areas should be at least 50 Pa when the doors are closed, and at least 15 Pa in the case of an open door. As stated at the beginning, this pressure difference is to prevent smoke from leaking from the usage area to the stair or elevator bucket.

Elevator Pressurization Systems:

The purpose of pressurization is to prevent smoke entry to fire elevators and to provide human evacuation in a smoke-free environment and to provide firefighters with a suitable means of transportation for fire response. According to the regulation on fire protection of buildings, a ventilation and smoke removal chimney should be located at least 0.1 m2 in the elevator shaft and 0.025 times the area of the well, or the wells should be pressurized.

About Fantürk

Our company is a company that produces technologies that give humanity a breather, aims to be a world-leading organization and tries to offer innovative technologies for the benefit of humanity. In the light of our experience, our company, which is sensitive to customer expectations, prioritizes quality, and adopts respect for business ethics and ethical beliefs, has a vision that aims to develop and grow. Our principle is to have a discipline that is sensitive to customer expectations, attaches importance to quality, and respects ethical values.

Our company has been operating in Bursa under the name of Havart Air Conditioning Limited Company and the brand name of Fantürk since 2002. In an area of 7000 m², it addresses the sector with the manufacture of air conditioning devices, automation system software and MCC-DDC panel manufacturing with our engineers and blue-collar employees who are experts in their branches.

In the light of our experience and knowledge, our company has a vision that is sensitive to customer expectations, prioritizing quality, and respecting business ethics and ethical beliefs. Attaching importance to R&D studies, Fantürk aims to increase its production and service quality based on international standards. Our main goal is to be a worldwide leader organization that produces technologies that breathe for all humanity by offering innovative technologies for the benefit of humanity.

Our Service and Product Categories

Duct Type Fans, Roof Type Fans, Heat Recovery, Parking Lot Ventilation, Stair and Elevator Pressurization, Snail Fan, Cell Fans, Air Handling Unit, Dust Collection System, Hot Air Appliance

Our products

- Y-KTF Round Duct Type Fan

- D-KTF Rectangular Duct Type Fan with External Motor

- SHS Duct Type Shelter Ventilation Device

- ÇTF (230V) Single Phase Roof Type Radial Fan

- ÇTF (380V) Three Phase Horizontal Discharge Roof Type Radial Fan

- ÇTF (380V) Three Phase Vertical Discharge Roof Type Radial Fan

- Ç-FWA Roof Type Axial Fan

- IGK Ceiling Type Heat Recovery Device

- J-FWA Axial Jet Fan

- R-FWA Radial Jet Fan

- Y-FWA Axial Smoke Exhaust Fan

- P-FWA Axial Fresh Air Fan

- Car Park Ventilation System Automation Panel

- Pressurization System Automation Panel

- ABF Low Pressure Snail Fan

- OBF Medium Pressure Snail Fan

- ECO Series Forward Curved Closed Blade Cell Fan

- M-HA Metal Oil Filter Cell Kitchen Aspirator

- H-FWA Cell Axial Fans

- FKS Air Handling Unit

- HNS Pool Dehumidification Unit

- TT Dust Collection System

- R-APA Radial Fan Hot Air Appliance

- A-APA Axial Fan Hot Air Appliance

- FRTT Rooftop Roof Type Air Handling Unit

- T-FWA Tunnel Jet Fan