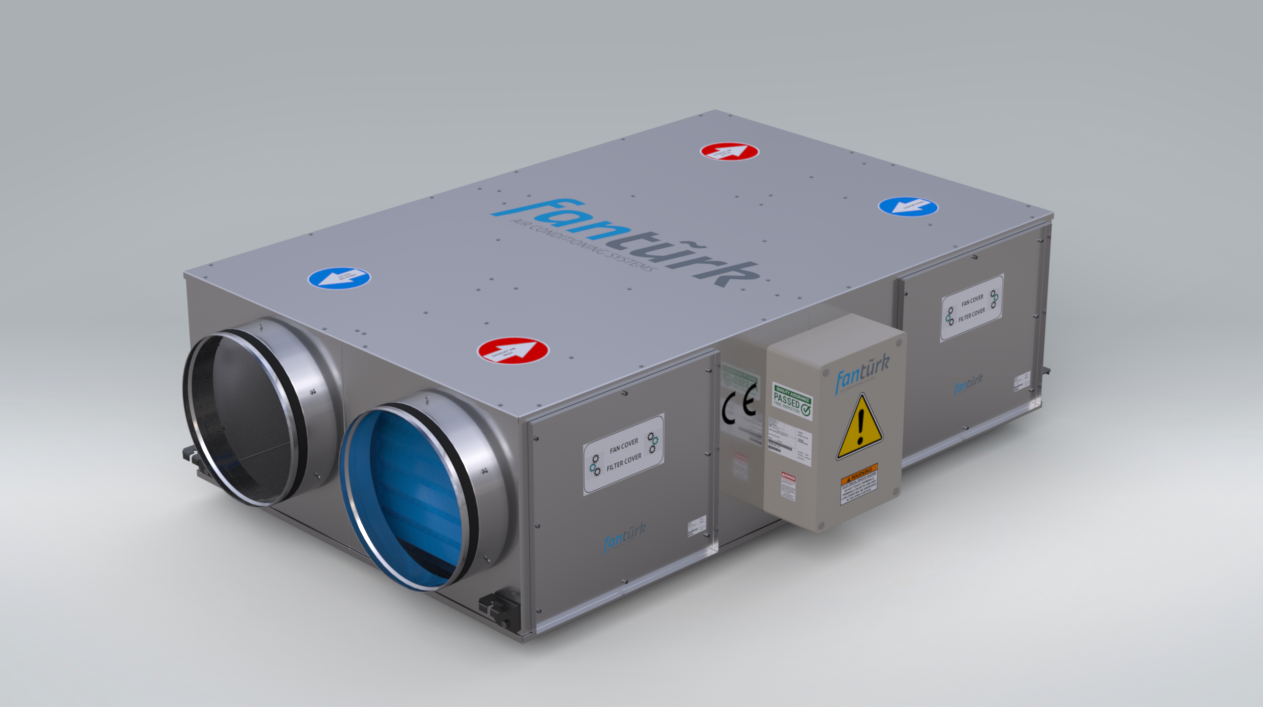

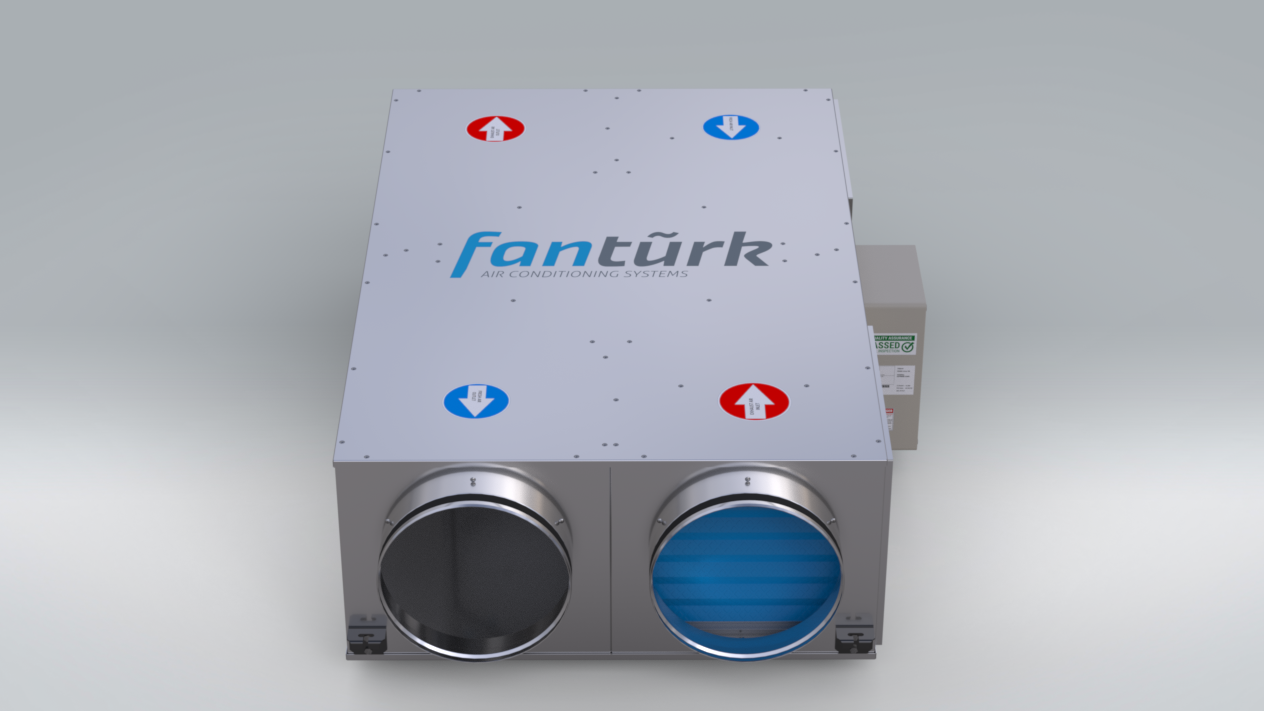

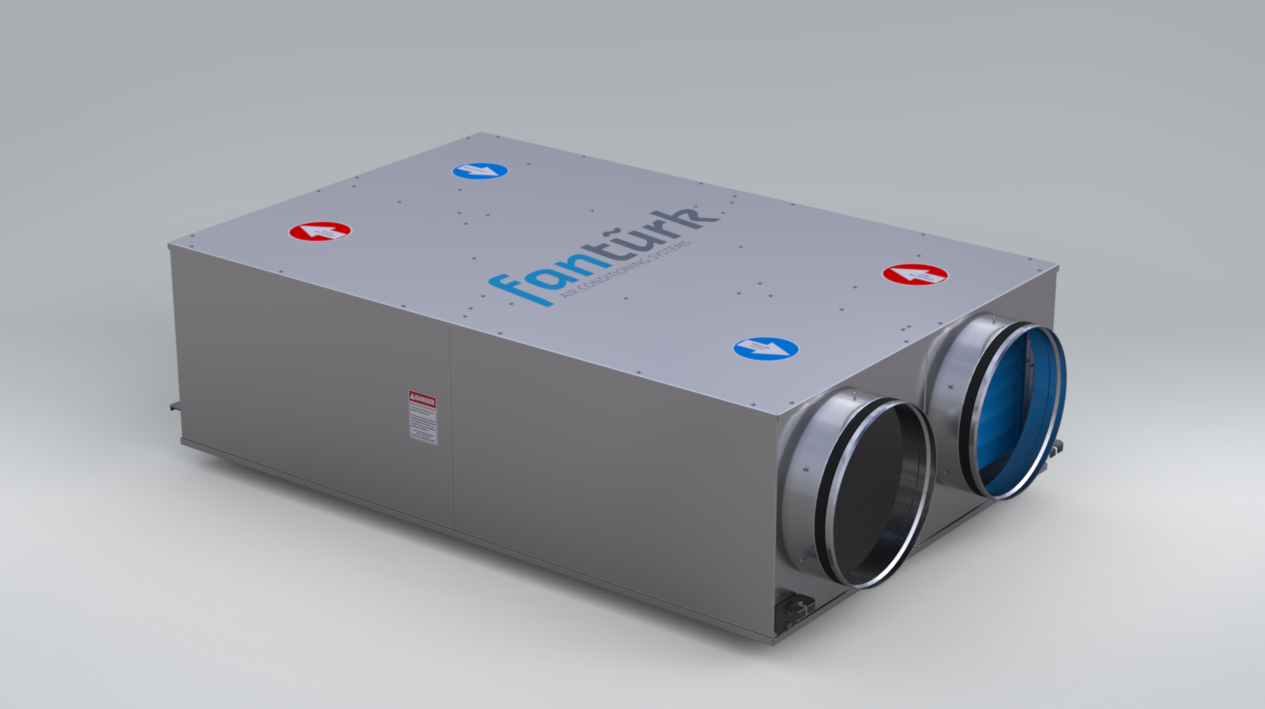

Ceiling Type Heat Recovery Device is manufactured from high quality corrosion resistant galvanized steel. The fans are radial fans with directly coupled backward curved blades. There are G4 filters in both directions. Heat recovery is provided by an aluminum plate recuperator. The IGK series is the ideal choice for high performance and trouble-free operation. Electric Heater, DX Coil, Water Coil can be integrated. Easy to use and manage with the control panel and control panel. It can be used in all kinds of office, school, hospital, cafe, restaurant and residential ventilation where both exhaust and fresh air are needed.

Ceiling type heat recovery device is used to provide more energy saving besides providing ambient ventilation. It saves energy while ventilating in environments where fresh air and exhaust are needed. The working principle of these devices is basically to expel the unwanted air in the environment and to transfer the usable energy in this air to the fresh air by means of a plate recuperator. With this principle, it can be said that it provides complete energy savings.

In particular, the ceiling type heat recovery device heats the air taken in during the winter months and cools the hot air taken in during the summer months. Thus, it reduces operating costs thanks to its energy savings. While this energy saving process takes place, heat recovery devices do not use any energy source, only the fans working for ventilation consume electrical energy.

Heat recovery devices, on the one hand, remove the unwanted air from the environment, on the other hand, they allow the necessary air to enter the environment in the desired way. In other words, it does not mix the two airs and does all this by itself. On the one hand, it continues the ventilation process and on the other hand, it saves energy. While taking the fresh air in, it also sends the heat energy in the unwanted air expelled by transferring it to the fresh air side. That’s why it saves a lot for you. You can also buy a heat recovery device from our company and have it mounted on the ceiling. And this way, a large amount of your money stays in your pocket.

Heat recovery devices that contain both aspirator and ventilator devices have many advantages. The first of these is to save energy to a great extent. Because on the one hand, it sends unwanted air to the outside. On the other hand, it takes the desired fresh air inside. Moreover, in this process, it takes advantage of the heat energy in this air while sending the unwanted air to the outside. Thus, the air needed by the environment is provided more quickly. At the same time, great energy savings are achieved. You can contact our company immediately to have this heat recovery device.

General Features of IGK Ceiling Type Heat Recovery Device

- High efficiency backward curved sparse bladed plug fans for lower energy consumption,

- High thermal efficiency aluminum plate heat exchanger,

- Low sound level,

- High static pressure,

- G4 class filter,

- Stepless speed control,

- Optional addition of water coil, DX coil, electric heater,

- Optional By-Pass option,

- Easy installation with optional duct type circular silencer

- Optional smart automation solutions

Working Principle of IGK Ceiling Type Heat Recovery Device

IGK Heat Recovery Device consists of 6 main parts. The case is made of galvanized sheet. It is covered with 6mm rubber insulation, providing both sound and heat insulation. The blowing and exhaust fans used are Plug Fans. It can be manufactured as Aluminum, Galvanized or Plastic. There are Intervention Covers on the case to easily interfere with the fans and filters. By means of these covers, the fans can be easily removed in case of maintenance or malfunction. There is a G4 filter at both the exhaust and fresh air inlets of the device. In this way, the Aluminum Plate Heat Exchanger, which is the main equipment of the device, is kept clean and working efficiently. In order to easily connect the device to the mains, the Electrical Connection Box, where the terminal connections of the fans are located, is fixed on the case.

In places that are air-conditioned by heating or cooling, low quality air-conditioned indoor air is formed, which contains carbon dioxide and other harmful gases in the indoor environment. While this air is exhausted, the heat load it carries is collected in the plate heat exchanger of the IGK — Heat Recovery Device, thus conditioning the incoming fresh air. In this way, it is possible to recover 50-60% of the heat load in this air while the poor quality indoor air is discharged. With the plug fan motors on these devices, they work silently and with high efficiency. With the speed switch sent as standard with the product, the device can be operated at the desired flow rate.

Main Components of IGK Ceiling Type Heat Recovery Device

1-Plug Fan AC

- Back curved sparse blade structure

- High efficiency

- Low power consumption

- Low sound level

- High static pressure

- Thermo-protective element against overheating of the motor

- Easy disassembly and service possibility with service cover and cable connection with connector

2-Heat Recovery Exchanger

- Long life aluminum plate type heat recovery exchanger

- High sensible heat transfer efficiency

- Sound dampening feature

- Easy disassembly and service possibility with the service cover

- Washability

- Eurovent Certificate

3-Speed Switch (Optional)

- Glass Insurance

- Electronic Potentiometer

- Infinite speed adjustment in the Minimum and Maximum voltage range

4-Digital Control Panel and Control Panel (Optional)

- Offers many available functions and external sensor connectivity.

However, other Option Models are IGK with Water Battery, IGK with By-Pass and IGK with Heat Pump.

IGK Ceiling Type Heat Recovery Device Control Panel and Control Panel

- Automatic or Manual program selection

- Easy to use with ready scenarios

- Possibility of integration with electric heater, DX coil, Water coil systems

- Modbus system usage possibility

- Aspirator and Ventilator Fan speed adjustment

- Additional heater equipment setting

- Ventilation in continuous comfort conditions with integrated room thermostat

a-) Available Functions

- Single Speed Fan Proportional Speed Control

- Three Speed Fan Speed Control*

- EC Fan Control(0-10V)*

- Electric Heater Control

- Preheater Control*

- Air Quality and CO2 Control

- Proportional Heating / Cooling Control*

- On / Off Heating / Cooling Control

- By-Pass Damper Control*

- DX Battery Freeze Protection*

- Recuperator Freeze Control

- Compressor Control*

- Filter Contamination Control

- Remote Control Possibility

- Weekly Calendar

- Modbus RTU Communication

- BACnet MS/TP Communication

b-) External Sensor Connections

- Return Air Sensor

- Supply Air Sensor

- Fresh Air Sensor

- Exhaust Air Sensor

- Air Quality Sensor

- CO2 Sensor

- Humidity Sensor *

Ceiling Type Heat Recovery Device Technical Specifications

1- Duct Type Electric Heater

- It has TSEK Quality Certificate and CE mark.

- It is used at the exit of the heat recovery device in cold climates and at the fresh air inlet against freezing in very cold climates.

- It can be designed as single, double or three-stage according to customer needs.

- It can be produced with galvanized or stainless steel body according to the project requirements..

- It has limit over-temperature breaker to be activated at 70°C and reset over-temperature breaker to activate at 110°C temperatures.

2- Round Duct Type Electric Heater Power Range

- 0.5 kW – Max. 15 kW

- Round Duct Type Electric Heater Dimensions

- Ød: Min. 100 mm / Max. 500 mm

- L: Standart 380 mm / Max. 500 mm

- A: Min. 275mm / Max. 395mm

- B: Standard 200 mm

- C: Standard 75 mm / 220 mm if Control Equipment

IGK Ceiling Type Heat Recovery Device Models

- IGK 500 Model

- Flow 500 m³/h

- Voltage 230 V

- Frequency 50 Hz

- Power 2×66 W

- Current 2×0,3 A

- Condensator 2×3 µf

- Cycle 2300 d/d

- Noise Level 42 dBA

- Weight 35 kg

- Electrical heater 1 kW-1 Kd

IGK 750 Model

- Flow 750 m³/h

- Voltage 230 V

- Frequency 50 Hz

- Power 2×100 W

- Current 2×0,47 A

- Condensator 2×3 µf

- Cycle 2580 d/d

- Noise Level 44 dBA

- Weight 45 kg

- Electrical heater 2 kW-1 Kd

IGK 1000 Model

- Flow 1000 m³/h

- Voltage 230 V

- Frequency 50 Hz

- Power 2×150 W

- Current 2×0,65 A

- Condensator 2×4 µf

- Cycle 2680 d/d

- Noise Level 47 dBA

- Weight 55 kg

- Electrical heater 3 kW-1 Kd

IGK 1500 Model

- Flow 1500 m³/h

- Voltage 230 V

- Frequency 50 Hz

- Power 2×200 W

- Current 2×0,9 A

- Condensator 2×6 µf

- Cycle 2650 d/d

- Noise Level 48 dBA

- Weight 60 kg

- Electrical heater 3 kW-1 Kd

IGK 2000 Model

- Flow 2000 m³/h

- Voltage 230 V

- Frequency 50 Hz

- Power 2×250 W

- Current 2×1,1 A

- Condensator 2×8 µf

- Cycle 2500 d/d

- Noise Level 48 dBA

- Weight 105 kg

- Electrical heater 5 kW-1 Kd

IGK 3000 Model

- Flow 2500 m³/h

- Voltage 230 V

- Frequency 50 Hz

- Power 2×210 W

- Current 2×1 A

- Condensator 2×8 µf

- Cycle 1400 d/d

- Noise Level 49 dBA

- Weight 130 kg

- Electrical heater 7 kW-1 Kd

IGK 4000 Model

- Flow 4000 m³/h

- Voltage 230 V

- Frequency 50 Hz

- Power 2×500 W

- Current 2×1,8 A

- Condensator 2×12 µf

- Cycle 1380 d/d

- Noise Level 52 dBA

- Weight 165 kg

- Electrical heater 10 kW-1 Kd

IGK 5000 Model

- Flow 5000 m³/h

- Voltage 230 V

- Frequency 50 Hz

- Power 2×800 W

- Current 2×3,7 A

- Condensator 2×16 µf

- Cycle 1350 d/d

- Noise Level 53 dBA

- Weight 210 kg

- Electrical heater 13 kW-1 Kd

IGK 6500 Modeli

- Flow 6500 m³/h

- Voltage 230 V

- Frequency 50 Hz

- Power 2×1550 W

- Current 2×6,8 A

- Condensator 2×31 µf

- Cycle 1380 d/d

- Noise Level 53 dBA

- Weight 210 kg

- Electrical heater 15 kW-1 Kd

About Fantürk

Our company is a company that produces technologies that give humanity a breather, aims to be a world-leading organization and tries to offer innovative technologies for the benefit of humanity. In the light of our experience, our company, which is sensitive to customer expectations, prioritizes quality, and adopts respect for business ethics and ethical beliefs, has a vision that aims to develop and grow. Our principle is to have a discipline that is sensitive to customer expectations, attaches importance to quality, and respects ethical values.

Our company has been operating in Bursa under the name of Havart Air Conditioning Limited Company and the brand name of Fantürk since 2002. In an area of 7000 m², it addresses the sector with the manufacture of air conditioning devices, automation system software and MCC-DDC panel manufacturing with our engineers and blue-collar employees who are experts in their branches.

In the light of our experience and knowledge, our company has a vision that is sensitive to customer expectations, prioritizing quality, and respecting business ethics and ethical beliefs. Attaching importance to R&D studies, Fantürk aims to increase its production and service quality based on international standards. Our main goal is to be a worldwide leader organization that produces technologies that breathe for all humanity by offering innovative technologies for the benefit of humanity.

Our Service and Product Categories

Duct Type Fans, Roof Type Fans, Heat Recovery, Parking Lot Ventilation, Stair and Elevator Pressurization, Snail Fan, Cell Fans, Air Handling Unit, Dust Collection System, Hot Air Appliance

Our products

- Y-KTF Round Duct Type Fan

- D-KTF Rectangular Duct Type Fan with External Motor

- SHS Duct Type Shelter Ventilation Device

- ÇTF (230V) Single Phase Roof Type Radial Fan

- ÇTF (380V) Three Phase Horizontal Discharge Roof Type Radial Fan

- ÇTF (380V) Three Phase Vertical Discharge Roof Type Radial Fan

- Ç-FWA Roof Type Axial Fan

- IGK Ceiling Type Heat Recovery Device

- J-FWA Axial Jet Fan

- R-FWA Radial Jet Fan

- Y-FWA Axial Smoke Exhaust Fan

- P-FWA Axial Fresh Air Fan

- Car Park Ventilation System Automation Board

- Pressurization System Automation Panel

- ABF Low Pressure Snail Fan

- OBF Medium Pressure Snail Fan

- ECO Series Forward Curved Dense Bladed Cell Fan

- M-HA Metal Oil Filter Cell Kitchen Aspirator

- H-FWA Cell Axial Fans

- FKS Air Handling Unit

- HNS Pool Dehumidification Unit

- TT Dust Collection System

- R-APA Radial Fan Hot Air Appliance

- A-APA Axial Fan Hot Air Apparatus

- FRTT Rooftop Roof Type Air Handling Unit

- T-FWA Tunnel Jet Fan

It is made of high quality corrosion resistant galvanized steel. The fans are radial fans with directly coupled back curved blades. There are G4 filters in both directions. Heat recovery is provided by an aluminum plate recuperator. The IGK series is the ideal choice for high performance and trouble-free operation.

Electric Heater, DX Coil, Water Coil can be integrated. Easy to use and manage with the control panel and control panel.

Usage Areas

It can be used in all kinds of office, school, hospital, cafe, restaurant and residential ventilation where both exhaust and fresh air are needed.

Ceiling Type Heat Recovery Device

Ceiling type heat recovery device is used to provide more energy saving besides providing ambient ventilation. It saves energy while ventilating in environments where fresh air and exhaust are needed. The working principle of these devices is basically to expel the unwanted air in the environment and to transfer the usable energy in this air to the fresh air by means of a plate recuperator.

With this principle, it can be said that it provides complete energy savings. In particular, the ceiling type heat recovery device heats the air taken in during the winter months and cools the hot air taken in during the summer months. Thus, it reduces operating costs thanks to its energy savings. While this energy saving process takes place, heat recovery devices do not use any energy source, only the fans working for ventilation consume electrical energy.

What Does Ceiling Type Heat Recovery Device Do?

Heat recovery devices, on the one hand, remove the unwanted air from the environment, on the other hand, they allow the necessary air to enter the environment in the desired way. In other words, it does not mix the two airs and does all this alone. On the one hand, it continues the ventilation process and on the other hand, it saves energy.

While taking the fresh air in, it also sends the heat energy in the unwanted air expelled by transferring it to the fresh air side. So it saves a lot of money for you. You can also buy a heat recovery device from our company and have it mounted on the ceiling. And in this way, a large amount of your money stays in your pocket.

Ceiling Type Heat Recovery Device Advantages

Heat recovery devices, which contain both aspirator and ventilator devices, have many advantages. The first of these is to save energy to a great extent. Because on the one hand, it sends unwanted air to the outside. On the other hand, it takes the desired fresh air inside.

Moreover, in this process, it takes advantage of the heat energy in this air while sending the unwanted air to the outside. Thus, the air needed by the environment is provided more quickly. At the same time, great energy savings are achieved. You can contact our company immediately to have this heat recovery device.