Axial Fan CFD Analysis: A Fanturk Perspective

In the realm of advanced ventilation and air circulation, Axial Fan CFD (Computational Fluid Dynamics) analysis emerges as a powerful tool that enables precision engineering and design. Fanturk, a prominent player in the air conditioning system industry, recognizes the significance of CFD analysis in optimizing fan performance and enhancing indoor comfort. This article delves into the world of Axial Fan CFD analysis, shedding light on its applications, benefits, and the role it plays in elevating the efficiency and effectiveness of modern air circulation systems.

Understanding Axial Fan CFD Analysis

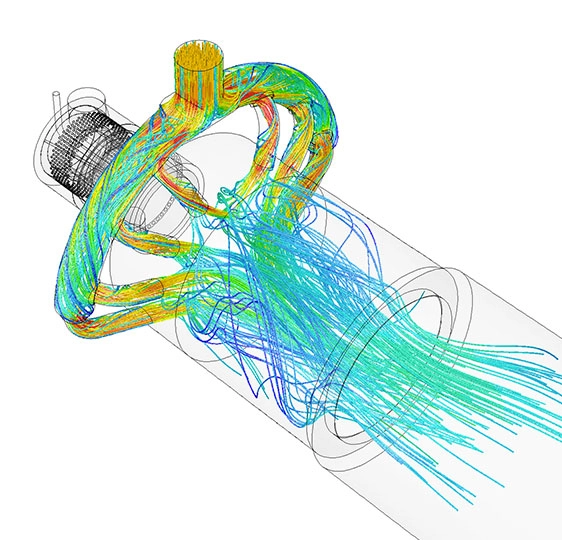

Axial Fan CFD analysis is a sophisticated computational technique that simulates fluid flow and heat transfer within axial fan systems. It leverages mathematical equations and algorithms to create a virtual environment, allowing engineers to visualize and analyze airflow patterns, temperature distribution, pressure differentials, and other critical parameters. By virtually testing different designs and configurations, CFD analysis empowers engineers to make informed decisions that optimize fan performance, efficiency, and overall system design.

Applications of Axial Fan CFD Analysis

- Optimized Fan Design: CFD analysis plays a pivotal role in the design phase, allowing engineers to evaluate various blade profiles, angles, and geometries to achieve optimal airflow performance.

- Efficiency Enhancement: Through CFD simulations, engineers can identify areas of turbulence or inefficient airflow, enabling them to make design adjustments that maximize fan efficiency and minimize energy consumption.

- Noise Reduction: Axial Fan CFD analysis helps identify potential sources of noise generation within the fan system. By optimizing airflow paths and reducing turbulence, engineers can design quieter and more acoustically friendly fan systems.

- System Integration: CFD analysis extends beyond the fan itself, providing insights into how the fan integrates with other components within the air conditioning system, such as ductwork, grilles, and diffusers.

Benefits of Axial Fan CFD Analysis

- Accurate Insights: CFD simulations provide engineers with accurate and detailed insights into airflow behavior, pressure distribution, and temperature gradients, enabling informed design decisions.

- Time and Cost Savings: Traditional physical prototyping and testing can be time-consuming and costly. Axial Fan CFD analysis accelerates the design process by allowing engineers to explore multiple design iterations virtually before physical production.

- Optimized Performance: By fine-tuning fan design parameters through CFD analysis, engineers can achieve superior fan performance, resulting in increased efficiency and reduced energy consumption.

- Noise Prediction and Control: CFD analysis can predict noise levels generated by the fan system, enabling engineers to implement design modifications that mitigate noise and vibrations.

- Environmental Impact: Optimized fan designs with reduced energy consumption contribute to environmental sustainability by lowering carbon footprints and energy usage.

Fanturk’s Approach to Axial Fan CFD Analysis

As an industry leader, Fanturk leverages CFD analysis to enhance the design and performance of its air conditioning systems. Through meticulous simulations, Fanturk’s engineering team fine-tunes axial fan designs to deliver optimal airflow, efficiency, and comfort. By employing CFD analysis, Fanturk aligns its commitment to innovation and precision engineering with the ever-evolving demands of the air conditioning industry.

The CFD Process: From Simulation to Application

The analysis process involves several key steps:

- Geometry Creation: The fan geometry is digitized and converted into a virtual model that accurately represents the physical fan.

- Mesh Generation: A computational grid (mesh) is created around the fan geometry. The mesh quality significantly affects the accuracy and speed of the simulation.

- Physics Setup: Boundary conditions, fluid properties, and airflow parameters are defined to replicate real-world conditions.

- Simulation Run: The CFD software solves the mathematical equations that govern fluid flow and heat transfer, generating detailed results.

- Analysis and Interpretation: Engineers analyze the simulation results to gain insights into airflow patterns, pressure distribution, temperature gradients, and other critical parameters.

- Optimization and Design Refinement: Based on the analysis, engineers fine-tune fan design parameters to optimize performance, efficiency, and noise levels.

Conclusion

analysis represents a transformative approach to designing and optimizing air circulation systems. Fanturk’s utilization of CFD analysis underscores the company’s commitment to innovation, efficiency, and precision engineering. By harnessing the power of CFD simulations, Fanturk elevates its air conditioning systems to new heights of performance, ensuring that clients receive cutting-edge solutions that prioritize indoor comfort, energy efficiency, and environmental sustainability. As the industry evolves, Fanturk continues to lead the way in leveraging technology to enhance the world of ventilation and air circulation.