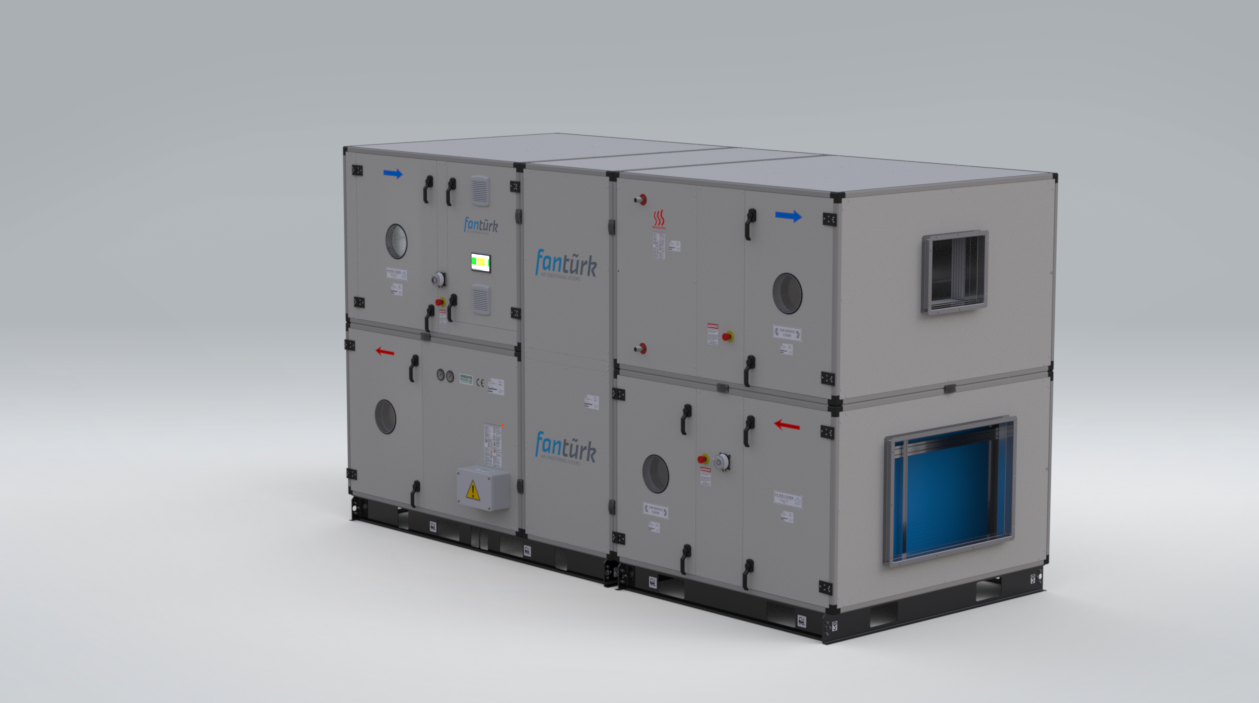

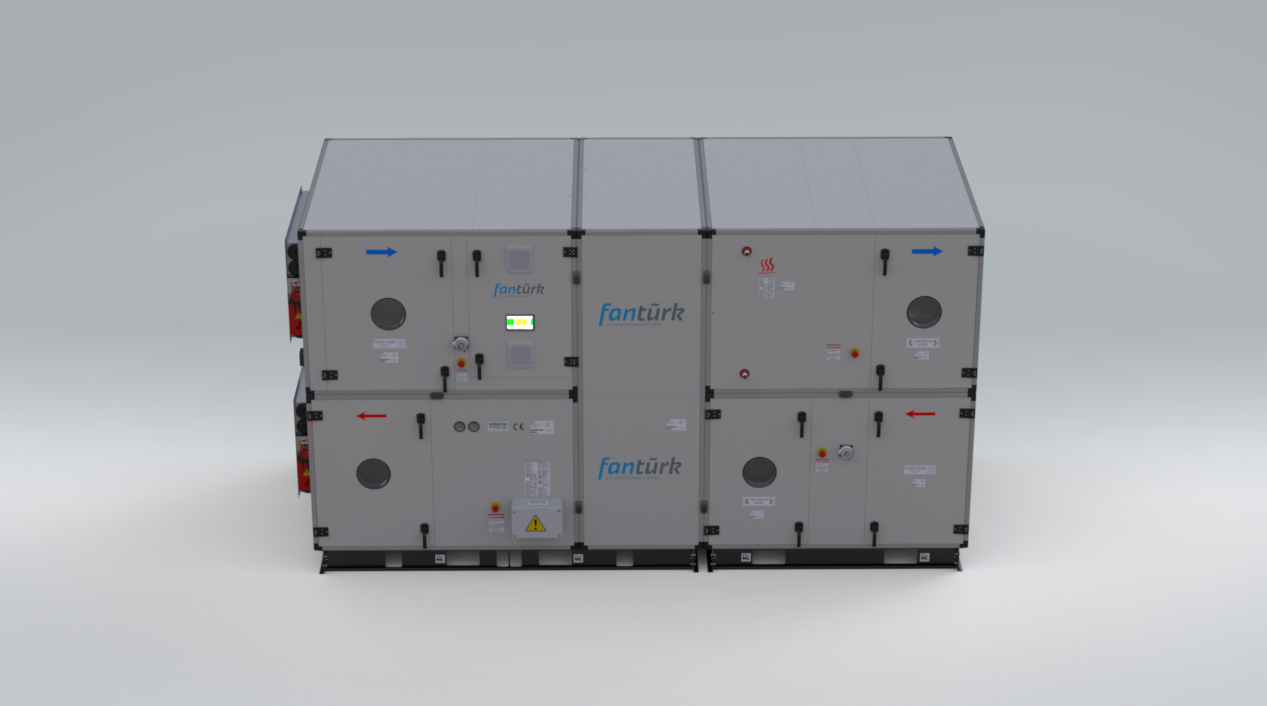

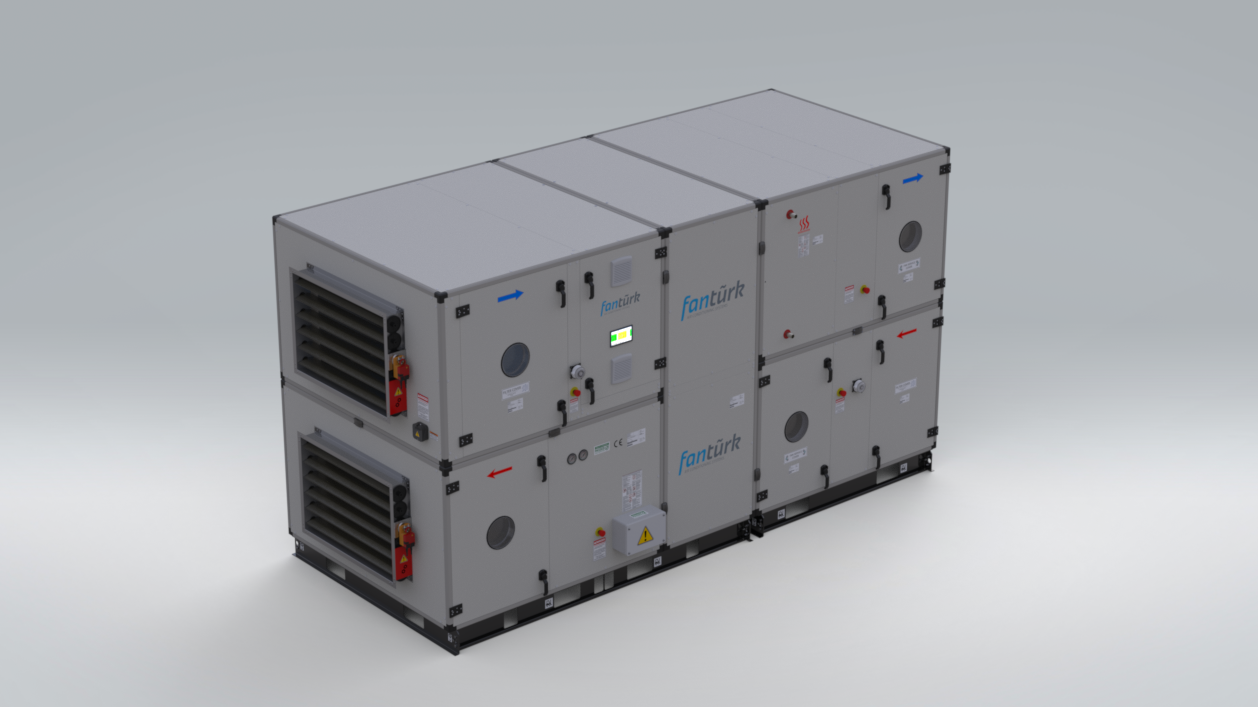

HNS Pool Dehumidification Unit; Special extruded aluminum profiles and panels are used for the HNS Pool Dehumidification Unit. Aluminum profiles are painted with corrosion resistant electrostatic oven. Profiles are joined to each other with specially designed plastic corners. The panels are produced in standard sizes, double-walled and rock wool is used as insulation material between them. Panel thickness is 50 mm.

The outer sheet of the panels is painted with protective polyfilm in RAL 9002 color as standard, and the inner surfaces are manufactured from galvanized sheet as standard and optionally from stainless sheet. Sheet thickness is 1 mm. The panels are removable from the outside of the switchboard. The inner surfaces of the central construction are designed as completely indented and protruding. The panels are attached directly to the profiles with special self-drilling screws.

EPDM based sealing gaskets are adhered between the panels and the profiles. Sealed gasketed service doors are installed where necessary on the switchboard. Service doors are manufactured with sight glass. The base of the plant can be in one piece or in pieces on the basis of cells, depending on the size of the plant. The device is placed on a 150 mm pedestal. There are lifting holes on the base for easy transport. In outdoor devices, it is ensured that the device is protected from external weather conditions by means of a specially designed roof.

Fantürk branded HNS series Pool Dehumidification Units are manufactured to be modular with a unique design. The central consists of three different cells. Thanks to this unique design, convenience is provided during transportation and assembly. Optionally, the switchboard can be shipped in a single structure or in a cell-by-cell or disassembled form and mounted at the construction site. Cells can be connected to each other with special fasteners. Special EPDM gasket is used to seal the mating surfaces.

If the partial pressure of the water vapor in the ambient air is lower than the saturation pressure, evaporation occurs on the surface of the pool water. Large amounts of water are constantly evaporating in indoor swimming pools. As a result, the amount of moisture in the air rises to an undesirable level.

Due to the high humidity in the air, perspiration occurs on the windows and walls, which causes corrosion and fungus formation in the building components. In addition to the destruction of building components, it also causes disorders such as decreased blood circulation and reduced athletic capacity in humans. The humidity rate in indoor swimming pools should be between 40%-64% according to VDI 2089 /1. As a result, it is possible to eliminate these negative effects with dehumidification, that is, by keeping the humidity values in comfort conditions.

HNS Pool Dehumidification Unit Technical Specifications

- Fantürk branded HNS series Pool Dehumidification units are modular in structure and have double-walled panels.

- The panels used are 50 mm thick and produced using rock wool insulation material.

- The outer surfaces are painted in RAL 9002 color as standard, and galvanized sheet is used on the inner surfaces.

- The frame of the power plants creates a strong structure with specially designed electrostatic oven painted aluminum profiles and plastic corner fasteners. EPDM based gaskets are used to ensure impermeability.

- Copy type heat recovery units are used for energy efficiency, which is of great importance today.

- The fan-motor group is selected in the most efficient way by considering the air flow and total static pressure. Fans can be selected as forward curved dense blades, backward curved sparse blades, belt pulley or plug type according to the intended use and desired design criteria. Performance tests approved fans are used. The motors are in IP55 class as standard and comply with CE norms.

- The dampers used in pool dehumidification units are manufactured using aluminum profiles, aluminum blades and plastic-based gears. The gears are out of the airflow. It provides sealing between damper blades with specially shaped plastic gaskets.

Pool Dehumidifier Components

1-Fan ve Motor

Various fan types are presented in accordance with the air flow and total pressure drop in each section. Statically and dynamically balanced fans in accordance with international standards can have forward curved, backward curved or airfoil blades depending on the purpose of use and customer request. Fan-motor group is selected by considering high efficiency, low sound level and minimum energy consumption depending on air flow and total static pressure. In order to prevent vibration, the fan-motor group is connected to the device with spring isolators.

Bushing, fixed diameter pulleys are used as standard in our devices, and it is possible to use variable diameter pulleys optionally. SPZ, SPA, SPB and SPC belt types are available. The tension of the belt is provided by a special mechanism. There is a service door with a safety guard in the fan chamber for service and maintenance. In special cases, plug type fans are used and the motor is directly coupled. The motors are in IP55 protection class as standard and comply with CE norms. The motors are single-speed as standard, and double-speed motors can be used optionally. Frequency converter for motor speed control available as accessory.

2- Heater – Cooler Equipment

Heating and cooling processes are carried out with serpentines. Serpentine pipes can be copper or steel, fins can be aluminum, copper, steel, epoxy coated aluminum or epoxy coated copper. The collectors used are copper. The serpentine cassette is made of galvanized steel sheets. The test pressure is 20 Bar. It is designed to be easily taken out for maintenance. Special By-Pass sheets allow the air to pass only through the serpentine surface.

Air and refrigerant are designed as counter flow to ensure high efficiency. In hot and cold water coils, the water inlet is from the bottom and the water outlet is from the top. In the cooling coils, the coil surface area has been efficiently used, thanks to the condensation pan that is embedded in the panel. The condensation pan is manufactured from stainless steel sheet with double slopes. To keep the condensed water in the air after the cooling coil, a drop catcher whose blade material is made of PVC is used. In order to prevent air leakage and possible condensation between the heating and cooling coil water inlet-output pipes and the panel sheet, a rubber rosette is mounted on the pipe.

3- Compressor

HNS series Pool Dehumidification Units use scroll type compressors. All equipment used is protected against high temperature and current. R407C is used as refrigerant.

4-Filters

G4 filters are used in the suction and blowing lines of the pool dehumidifiers. Section dimensioning is done in accordance with international standards, taking into account the filtration surface area. The filters are cassette type and can be easily mounted and removed. Air leaks are prevented by appropriate designs. There is a service door for maintenance and replacement in the filter cells. Optionally, manometer, lighting and sight glass can be used.

5- Heat Recovery Cell

Today, energy efficiency is of great importance. For this reason, heat-pipe type heat recovery coil is preferred in heat recovery units in HNS series Pool Dehumidification Units. In this way, while efficiency is increased, energy consumption and operating costs are reduced to minimum levels.

In heat recovery elements with compact heat pipes, heat transfer is realized by phase difference of the fluid in the closed circuit due to the temperature difference of the exhaust and fresh air. No additional equipment is needed. There is no mixing of fresh air and exhaust air. It is easy to clean and maintain. They are preferred due to their long-lasting use. Heat pipes can be manufactured to be resistant to corrosion. There is a double inclined condensation pan under the heat pipe.

6- Controller

Pool dehumidification plants are systems that take the moisture on the air by cooling and reheating the air with its compressor structure. Pool dehumidifiers are used to dehumidify the pools of hotels, schools and private pool businesses. The HV-DHMC-1-M controller is designed for the control of pool dehumidification units with compressors. It is possible to control and monitor with building management systems.

Controller specifications;

- Connection to building management systems (Modbus-RTU)

- Fault inputs

- Enthalpy

- Weekly Program (Optional)

- Key lock

If the partial pressure of the water vapor in the ambient air is lower than the saturation pressure, evaporation occurs on the surface of the pool water. In indoor swimming pools, large amounts of water evaporate continuously. As a result, the amount of moisture in the air rises to an undesirable level. Due to the high humidity in the air, perspiration occurs on windows and walls, causing corrosion and fungus formation on building components. In addition to the destruction of building components, it also causes discomfort such as decreased blood circulation and decreased sports capacity in humans. Humidity in indoor swimming pools should be between 40% and 64% according to VDI 2089/1. As a result, it is possible to eliminate these negative effects by dehumidification, that is to keep the humidity values under comfort conditions.

●Fantürk HNS series Pool Dehumidification Units are modular type and have double skin panels.

●The panels used are 50mm thick and are produced by using stone wool insulation material.

●Outer surfaces are coated in RAL 9002 color as standard and galvanized sheet is used in inner surfaces.

●The case of the device forms a strong structure with specially designed electrostatic coated aluminum profiles and plastic corner fittings. EPDM based gaskets are used for sealing.

●Nowadays, heat-pipe type heat recovery units are used for energy efficiency which is very important.

●The fan-motor group is selected in the most efficient way considering the air flow and total static pressure. Fans can be selected with forward curved blades, backward curved blades and can be driven with belt-pulley or plug types according to the intended use and desired design criteria. Fans are approved with performance tests. The motors are IP55 class as standard and comply with CE norms.

●Dampers used in dehumidifications units are manufactured using aluminum profile, aluminum wing and plastic based gears. The gears are outside of the air flow.