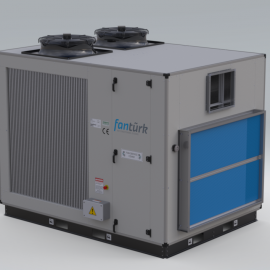

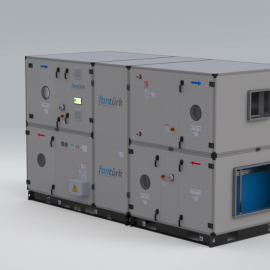

FKS Air Handling Unit; Specially drawn aluminum profiles and panels are used in Fanturk Air Handling Units. Aluminum profiles are painted with corrosion resistant electrostatic oven. Profiles are joined to each other with specially designed plastic corners. The panels are produced in standard sizes, double-walled and rock wool, glass wool or polyurethane is used as insulation material between them. Panel thickness is 50mm or 60mm. The outer sheet of the panels is painted with protective polyfilm in RAL 9002 color as standard, and the inner surfaces are manufactured from galvanized, stainless or painted sheet metal. Sheet thickness is between 0.8 – 1.2 mm. Panels are removable from outside the switchboard.

The inner surfaces of the central construction are designed as completely indented and protruding. The panels are attached directly to the profiles with special screws with drill bits. EPDM based sealing gaskets are adhered between the panels and the profiles. Sealed gasketed service doors are installed where necessary on the switchboard. Service doors can also be manufactured with (hygienic) sight glass upon request or according to the purpose of application.

The base of the plant can be in one piece or in pieces on the basis of cells, depending on the size of the plant. Air handling units are placed on a 150 mm pedestal. There are lifting holes on the base for easy transport. In outdoor devices, it is ensured that the device is protected from external weather conditions by means of a specially designed roof.

FKS Air Handling Unit Technical Specifications

FKS Air Handling Unit is manufactured in 28 different sections. The flow rate range is 900 m³/h- 145,000 m³/h in plants for cooling and ventilation purposes, and 900-194.000 m³/h in plants for heating purposes only. The air handling units produced are modular and have double-walled panels. It can be produced by using 50 mm or 60 mm thick panels with rock wool, glass wool or polyurethane insulation according to demand and application. The outer surfaces are painted sheet metal in the color of RAL 9002 as standard, and galvanized, painted or stainless steel sheet can be used on the inner surfaces according to demand and application. Thanks to its smooth inner surface, it is easy to clean and dust accumulation is prevented.

The frame of the power plants creates a strong structure with specially designed electrostatic oven painted aluminum profiles and plastic corner fasteners. EPDM based gaskets are used to ensure impermeability. Filter selections are made taking into account the environment in which the device operates and the needs of the process.

With special designs, leaks that may occur during air flow are prevented and high efficiency is achieved in the coils and filters. Plate, rotor or battery type heat recovery units are optionally used for energy efficiency, which is of great importance today. The fan-motor group is selected in the most efficient way by considering the air flow and total static pressure.

Fans can be selected as forward curved dense blades, backward curved sparse blades, belt pulley or plug type according to the intended use and desired design criteria. Performance tests approved fans are used. Motors are in IP55 class as standard and comply with CE norms.

Dampers used in air handling units are manufactured using aluminum profiles, aluminum blades and plastic-based gears. The gears are out of the airflow. It provides sealing between damper blades with specially shaped plastic gaskets. Optional lighting, sight glass, manometer, flexible connection at the discharge and suction openings, siphon, maintenance switch, damper motor, rain protection are used in the air handling units produced.

FKS Air Handling Unit Selection Program

The selection, sizing and the creation of the technical report containing the performance data of Fantürk air handling units can be easily done with the «FKS Air Handling Unit» selection program. With the air handling unit selection program, the most suitable section can be determined by seeing the air velocities in different device sections and on the serpentine surface according to the desired air flow. The desired device can be created by juxtaposing the specified elements.

According to the desired air flow rate, the most suitable section can be determined by seeing the air velocities in different device sections and on the serpentine surface. The desired device can be created by bringing the determined elements side by side. Accessories can be specified for each element. In the selection of each element, you can see the brand and model alternatives, if any, together with their price ratios, among the options, efficiency, price, etc. the most suitable one can be selected. The maximum cell size can be determined by how many parts the device will consist of. The dimensions and weights of the parts that make up the device can be seen. The technical report containing the price, sized picture and necessary information of the selected device can be printed.

FKS Air Handling Unit Components

1-Filters

The cross-section dimensioning of Fanturk air handling units is made in accordance with international standards, taking into account the filtration surface area. The filters are cassette type and can be easily mounted and removed. Air leaks are prevented by appropriate designs. There is a service door for maintenance and replacement in the filter cells. Optionally, manometer, lighting and sight glass are used. Considering the importance of indoor air quality in air handling units, filters of different types and efficiency are used.

Types of filters in general;

- Panel filter

- Metal filter

- Bag filter

- Activated carbon filter

- Compact filter

- Hepa filter

Panel filters are used as pre-filters. The filter material is synthetic or metallic. Metal filters have the feature of holding oil. The filter classes we use are G2, G3, G4 for synthetic material and G2, G3 for metallic material. Bag filters are used for high efficiency air filtration. Dust holding capacity is high. They should be used with a pre-filter to increase their life.

Bag sizes vary as 305 mm, 508 mm and 635 mm according to the air flow. The filter classes we use are G4, F5, F6, F7, F8. Activated carbon filters are used to absorb odorous gas or vapor molecules from the air (such as exhaust fumes, rubber odors, alcohol, hydrocarbons, chlorine, and odors emitted from other chemical production processes). An alternative model is available for absorbing odors emitted from other industrial processes such as hydrogen sulfide, sulfur dioxide. They should be used with a pre-filter to increase their life.

Compact filters are high efficiency filters. They should be used in conjunction with a pre-filter. Since their depth is 292 mm, they take up little space in the switchboard. Due to the filter structure, it is possible to distribute the air evenly over the entire filter surface. The filter classes we use are F6, F7, F8, F9. HEPA filters are used for hygienic environments. Their yield is very high. These filters are installed after the fan and must be used together with a pre-filter. The filter classes we use are H10, H12, H13, H14.

2- Heat Recovery Units

Today, energy efficiency is of great importance. For this reason, the use of heat recovery units in air handling units has started to be preferred. Heat recovery elements with heat pipes, plates and rotors are used in Fanturk air handling units.

Efficiency in heat recovery systems in general;

- 30-50% in heat pipe type heat recovery units,

- 40-60% in plate type,

- It varies between 60-80% in rotor type.

3- Electric heater

Electric heaters are optionally used in Fanturk air handling units. It is used at the entrance of the power plant in areas with high freezing risk. It is also used at the power plant outlet in sensitive systems that need instant heating. The electric heater cassette is optionally manufactured from galvanized or stainless steel. The elements are stainless material. The protection class is IP43. Gradual or proportional control can be done. It has CE certificate.

As standard, the heaters have an automatic reset limit thermostat and a manual reset safety thermostat. If the heater power is above 30 kW, it is recommended to run the fan of the plant for 2-3 more minutes after the electrical heater is de-energized. If there is an electrical heater in the air handling unit, it is absolutely necessary to take measures to disable the electrical heater in cases where the fan does not operate or operates at very low speeds (below 1.5 m/s).

4- Heater – Cooler Serpentine

Heating and cooling processes are carried out with serpentines. Serpentine pipes can be copper or steel, fins can be aluminum, copper, steel, epoxy coated aluminum or epoxy coated copper. Direct expansion coils are manufactured as copper pipes and aluminum fins and the collectors are copper. The serpentine cassette is made of galvanized steel sheets. The test pressure is 20 bar. In hot and cold water serpentines, the pipe inlet-outlet mouths are threaded; Pipe inlet and outlet ports are flanged in superheated water and steam coils.

It is designed to be easily taken out for maintenance. With special by-pass sheets, it is ensured that the air passes only through the serpentine surface. It is designed as air and water counter flow to ensure high efficiency. In hot and cold water coils, the water inlet is from the bottom and the water outlet is from the top. In the cooling coils, the coil surface area has been efficiently used, thanks to the condensation pan that is embedded in the panel. The condensation pan is manufactured from stainless steel sheet with double slopes. After the cooling coil, a separator is used to keep the condensed water in the air.

5-DX Battery

DX Coils minimize energy and heat loss as the heat transfer is made directly from the air by means of the refrigerant. In winter, it is necessary to use an electric or water type preheater or a freezing thermostat at low temperatures. Outdoor unit connections can be made easily. Maintenance and repair is very simple.

6-Fan ve Motor

Various fan types are presented in accordance with the air flow and total pressure drop in each section. Statically and dynamically balanced fans in accordance with international standards can have forward curved, backward curved or airfoil blades depending on the purpose of use and customer request. Fan-motor group is selected by considering high efficiency, low sound level and minimum energy consumption depending on air flow and total static pressure. In order to prevent vibration, the fan-motor group is connected to the device with spring isolators.

Bushing, fixed diameter pulleys are used as standard in our devices, and it is possible to use variable diameter pulleys optionally. SPZ, SPA, SPB and SPC belt types are available. The tension of the belt is provided by a special mechanism. There is a service door with a safety guard in the fan chamber for service and maintenance.

In special cases, plug type fans are used and the motor is directly coupled. The motors are in IP55 protection class as standard and comply with CE norms. The motors are single-speed as standard, and double-speed motors can be used optionally. A frequency converter for motor speed control is available as an accessory.

7-Muffler

The noise level, which is of great importance in ventilation systems, is reduced to an acceptable sound level in the area with the help of silencers. Sound absorption coefficient of silencers varies according to the silencer size used. The silencer cell consists of backstages in which rock wool is placed in galvanized or stainless steel sheets. Silencer elements are designed not to deform at 20 m/s air speed. 6 different silencer sizes are offered in Fanturk air handling units.

●Fantürk FKS Series Air Handling Units are manufactured in 28 different sections. Flow Rate range is 900 m³ / h – 145 .000 m³ / h for cooling and ventilation units and 900-194.000 m³ / h for heating units only.

●Air Handling Units manufacturing with modular type and have double-skin panels.

●According to demand and application, rockwool, glasswool or polyurethane insulation, 50 mm or 60 mm thickness can be used for panels.

●Exterior skins are coated in RAL 9002 color as standard and for inner skins galvanized, painted or stainless steel can be used according to the request and application.

●Thanks to its flat inner surface, it is easy to clean and prevents dust accumulation.

●The case of the air handling units forms a strong structure with specially designed electrostatic coated aluminum profiles and plastic corner fittings. EPDM based gaskets are used for sealing.

●Filter selections are made taking into consideration the environment and process requirements of the device.

●High efficiency is achieved in coils and filters by preventing leakages that may occur during air flow with special designs.

●Depends on request plate type, rotor type or heat-pipe type heat recovery units can be used for energy efficiency which is of great importance nowadays.

●The fan-motor group is selected in the most efficient way considering the air flow and total static pressure. Fans can be selected with forward curved blades, backward curved blades and can be driven with belt-pulley or plug types according to the intended use and desired design criteria. Fans are approved with performance tests. The motors are IP55 class as standard and comply with CE norms.

●Dampers used in air handling units are manufactured using aluminum profile, aluminum wing and plastic based gears. The gears are outside of the air flow