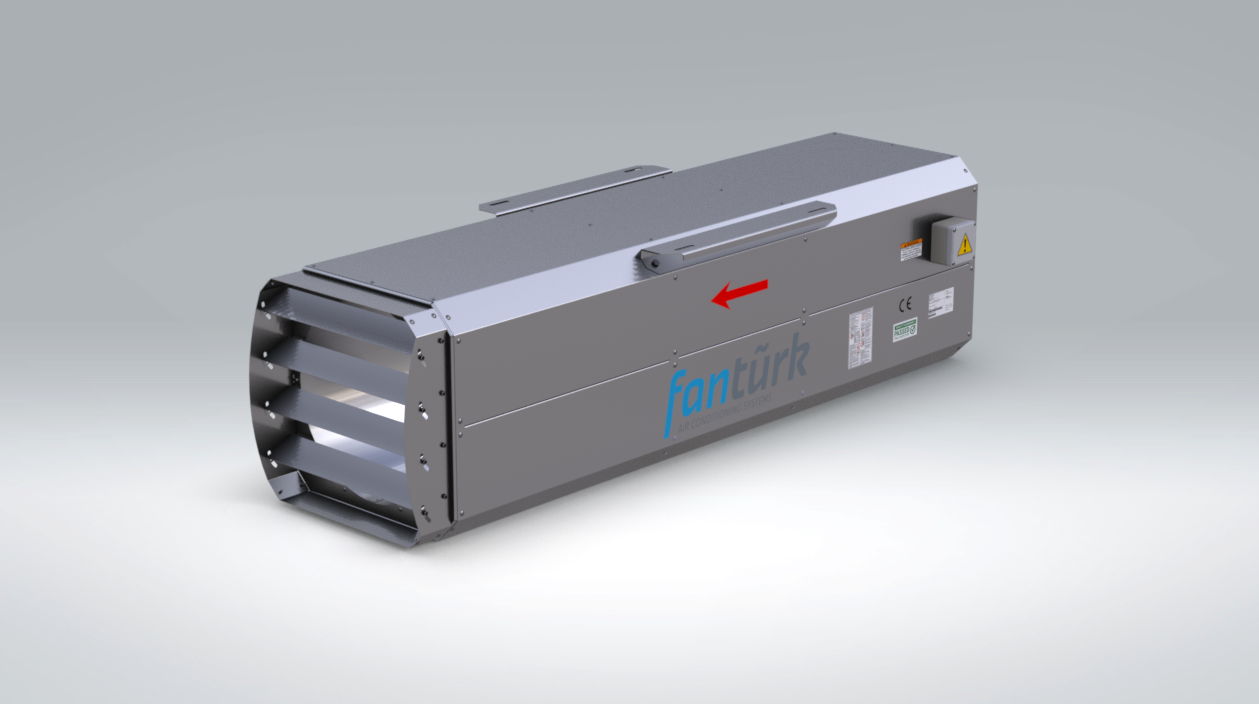

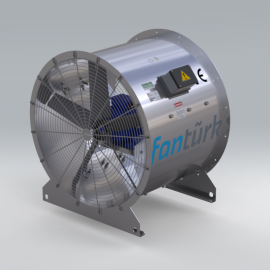

J-FWA Axial Jet Fan is manufactured from high quality corrosion resistant galvanized steel. The blade angles of the propellers used are adjustable and manufactured from special alloy aluminum. The products produced have been tested in international accredited institutions according to the EN 12101-3 Standard and are fire-certified as resistant to working at 400°C for 2 hours. It is manufactured between Ø315mm and Ø630mm diameters. According to the project used, there are two-way, one-way, double-speed, single-speed options.

J-FWA series is the ideal choice for high performance and trouble-free operation. It is suitable for use in all kinds of hotels, hospitals, residences, shopping malls, offices, residential parking lots ventilation systems. Thanks to its unique skid system design, disassembly and maintenance times are minimized with an easy intervention to the engine. Jet Fan systems, which we see in the indoor car parks of shopping malls, large hospitals and hotels, provide the evacuation of harmful gases such as exhaust gases from vehicles in the car park and daily ventilation of the car park. In addition, it also provides protection against possible dangers by having features such as the evacuation of smoke released in the event of a fire. Jet fan systems in car park ventilation are divided into two as Radial Jet Fans and Axial Jet Fans.

Axial jet fans are used in parking lots. A healthy ventilation of indoor parking lots is one of the biggest problems. Axial jet fan is one of the most suitable devices to solve this problem. Produced with Fantürk quality, Axyal Jet Fan is a product that has successfully passed all tests of internationally accredited organizations and is resistant to working at temperatures up to 400 degrees. There are two-way and one-way options, as well as double-speed and single-speed options, it can be preferred according to the characteristics of the area to be used.

J-FWA Axial Jet Fan General Features

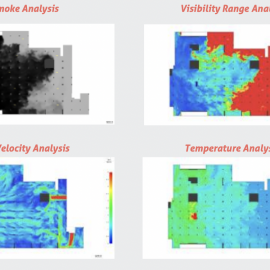

Axial jet fan systems ensure that the air, smoke or harmful exhaust gases in the environment are transmitted to the exit point in a controlled manner with the help of the low pressure areas they make on the working planes. Thanks to the high velocity of the air flow, the flow increases and maximum efficiency is achieved. With the use of axial jet fan systems, there is no need to perform operations such as grille and diffuser placement or duct installation, and energy and time savings are provided for the operation. The floor heights, which are designed as high, can be reduced so that traditional duct systems can be used. It is possible to easily carry out revision processes in architectural and mechanical project stages. By providing flexibility and ease of assembly, it prevents time loss in maintenance and repair operations.

The equipment of J-FWA Axial Jet Fan models are certified to EN 12101-3 fire resistant to 400 degrees for 2 hours and to 300 degrees for 2 hours by internationally recognized accreditation organizations. It is manufactured between Ø315 mm and Ø630 mm diameters. According to the project used, there are two-way, one-way, double-speed and single-speed options.

1-Fan Body

Propellers used in J-FWA Axial Jet Fan Models are made of ST 52 steel blades or body and blades with adjustable blade angles are made of special alloy aluminum. According to the project, it can operate with the same performance in both blowing directions, thanks to its reversible blade structure. Conforms to international standards.

2-Propeller

It is manufactured as a standard (380 V – 50 Hz) or on request in accordance with other voltages and frequencies (400 / 415/ 440 V – 50 Hz). As standard, Class H, S1+S2, IP55, resistant to 400 degrees for 2 hours or to 300 degrees for 2 hours, single speed or double speed motor is used.

3-Electric Motor

In these series, the sound intensity increases due to the high air outlet velocities and for this reason, jet fans are used with silencer as standard.

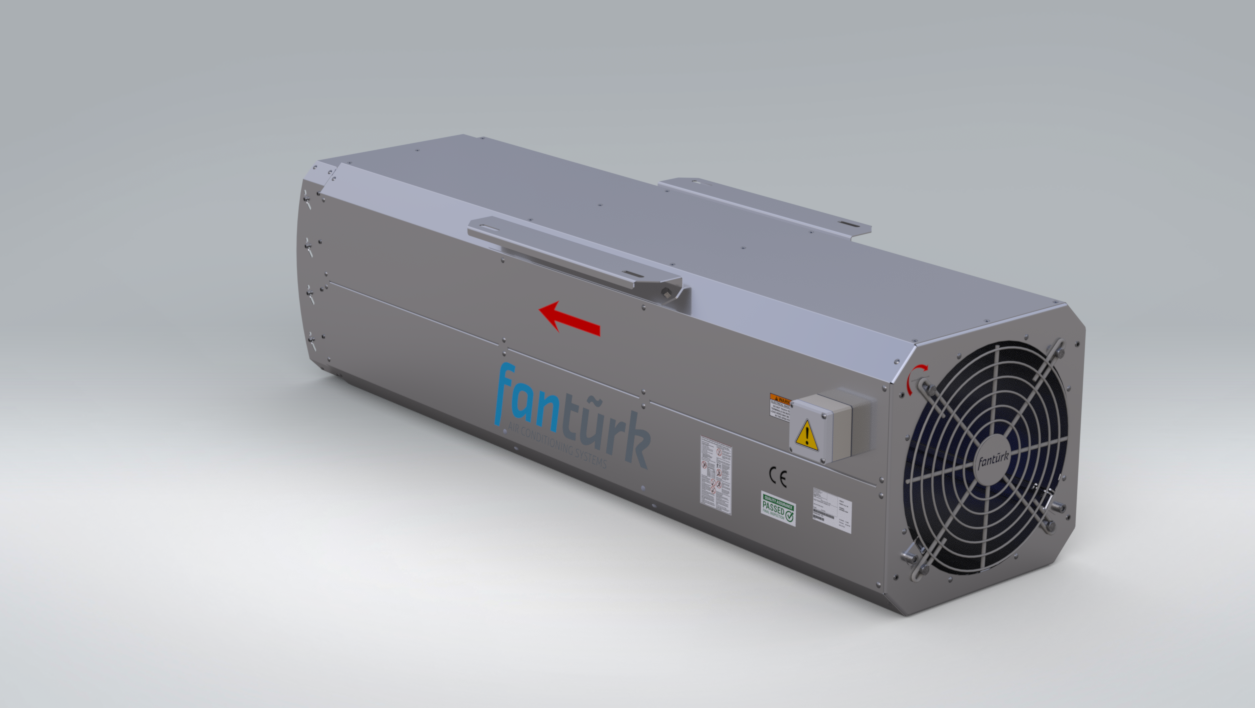

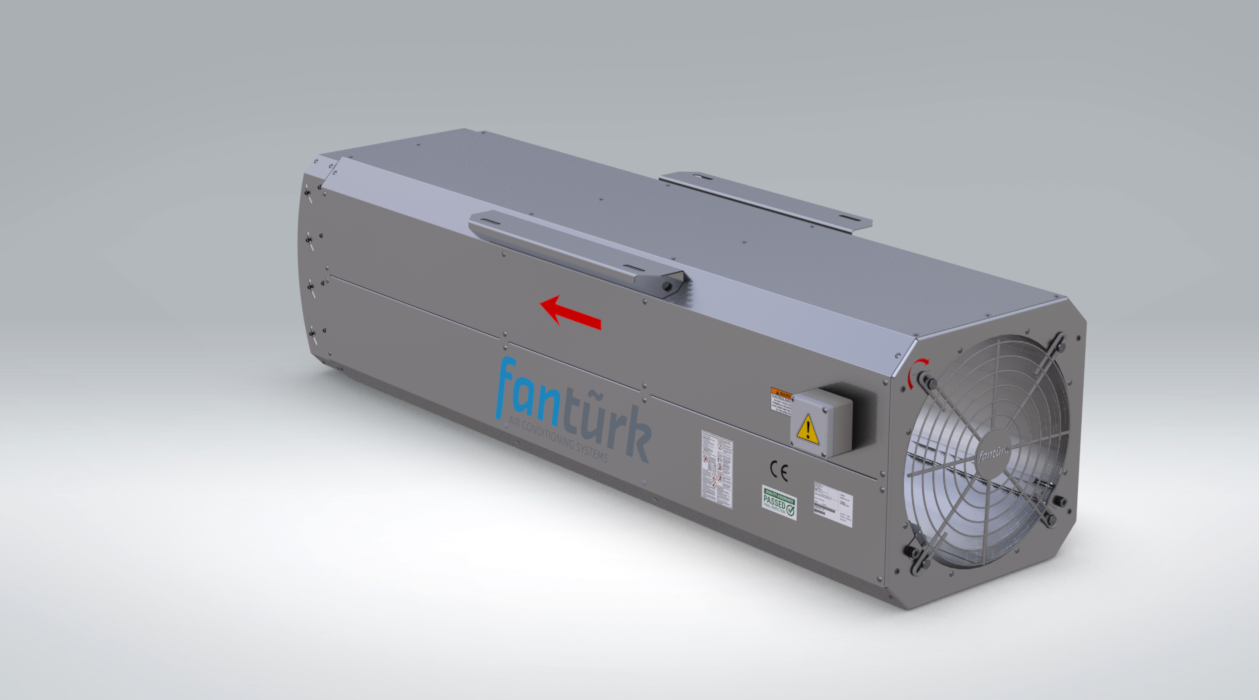

4-Slide System

Thanks to the specially designed skid system in J-FWA Models, easy intervention is provided to the engine and disassembly and maintenance times are minimized. Thanks to its special design, the engine can be easily accessed, the engine can be disassembled and reassembled. A sliding system was used in the design. All national and international certificates of the product are complete. All these features are produced on the basis of international standards.

5-Adjustable Propeller Angle

Axial Jet Fan is made of high quality galvanized sheet that has passed the highest durability tests. The propellers are adjustable in angle and produced from special aluminum alloy material. The sound intensity is high due to the very high air velocity during operation, therefore there is a silencer on the suction and discharge sides of the product.

6-Energy Saving with Automation System

Thanks to the integrated Fantürk Jet Fan Automation, it works fully equipped against all possible bad scenarios and prevents dangers in the area where it is used. It can evacuate smoke in the fastest way in case of fire. In addition, thanks to this automation, the fan works according to the information coming from the sensors that measure the carbon monoxide rate in the environment, thus providing significant energy savings.

About Fanturk

Our company has been operating in Bursa under the name of Havart Klima Ltd Şti and the brand name of Fantürk since 2002. In an area of 7000 m², it addresses the sector with the production of air conditioning devices, automation system software and MCC-DDC panel manufacturing with our engineers and blue-collar employees who are experts in their branches.

Fantürk is a company that produces technologies that give humanity a breather, aims to be a worldwide leader company and tries to offer innovative technologies for the benefit of humanity. In the light of our experience, our company, which is sensitive to customer expectations, prioritizes quality, and adopts respect for business ethics and ethical beliefs, has a vision that aims to develop and grow. Our principle is to have a discipline that is sensitive to customer expectations, attaches importance to quality, and respects ethical values.

In the light of our experience and knowledge, our company, which is sensitive to customer expectations, prioritizes quality, and adopts respect for business ethics and ethical beliefs, has a vision that aims to develop and grow. Attaching importance to R&D studies, Fantürk aims to increase its production and service quality based on international standards. Our main goal is to be a worldwide leader organization that produces technologies that breathe for all humanity by offering innovative technologies for the benefit of humanity.

Our Service and Product Categories

Duct Type Fans, Roof Type Fans, Heat Recovery, Parking Lot Ventilation, Stair and Elevator Pressurization, Snail Fan, Cell Fans, Air Handling Unit, Dust Collection System, Hot Air Appliance

Our Products

- Y-KTF Round Duct Type Fan

- D-KTF Rectangular Duct Type Fan with External Motor

- SHS Duct Type Shelter Ventilation Device

- ÇTF (230V) Single Phase Roof Type Radial Fan

- ÇTF (380V) Three Phase Horizontal Discharge Roof Type Radial Fan

- ÇTF (380V) Three Phase Vertical Discharge Roof Type Radial Fan

- Ç-FWA Roof Type Axial Fan

- IGK Ceiling Type Heat Recovery Device

- J-FWA Axial Jet Fan

- R-FWA Radial Jet Fan

- Y-FWA Axial Smoke Exhaust Fan

- P-FWA Axial Fresh Air Fan

- Car Park Ventilation System Automation Panel

- Pressurization System Automation Panel

- ABF Low Pressure Snail Fan

- OBF Medium Pressure Snail Fan

- ECO Series Forward Curved Closed Blade Cell Fan

- M-HA Metal Oil Filter Cell Kitchen Aspirator

- H-FWA Cell Axial Fans

- FKS Air Handling Unit

- HNS Pool Dehumidification Unit

- TT Dust Collection System

- R-APA Radial Fan Hot Air Appliance

- A-APA Axial Fan Hot Air Appliance

- FRTT Rooftop Roof Type Air Handling Unit

- T-FWA Tunnel Jet Fan

It is made of high quality corrosion resistant galvanized steel. The blade angles of the propellers used are adjustable and manufactured from special alloy aluminum. The products produced have been tested in international accredited institutions according to the EN 12101-3 Standard and are fire-certified as resistant to working at 400°C for 2 hours.

It is manufactured between Ø315mm and Ø630mm diameters. According to the project used, there are two-way, one-way, double-speed and single-speed options. J-FWA series is the ideal choice for high performance and trouble-free operation.

Usage Areas

It is suitable for use in all kinds of hotels, hospitals, residences, shopping malls, offices, residential parking lots ventilation systems.

Slide System

Thanks to its unique skid system design, disassembly and maintenance time is minimized with an easy intervention to the engine.

Jet Fan Systems

Shopping malls, large hospitals, hotels, etc. Jet Fan systems that we see in indoor parking garages provide protection against possible dangers by evacuating harmful gases such as exhaust gases from vehicles in the parking lot and daily ventilation of the parking lot, as well as evacuating the smoke released in the event of a fire. Jet fan systems in parking lot ventilation are divided into two as Radial Jet Fans and Axial Jet Fans.

Axial Jet Fan Features

Axial jet fans are used in parking lots. A healthy ventilation of indoor parking lots is one of the biggest problems. Axial jet fan is one of the most suitable devices to solve this problem. Produced with Fantürk quality, Axial Jet Fan is a product that has successfully passed all tests of internationally accredited organizations and is resistant to operating at temperatures up to 400 degrees. There are two-way and one-way options, as well as double-speed and single-speed options, it can be preferred according to the characteristics of the area to be used.

Adjustable Propeller Angle

Axial Jet Fan is made of high quality galvanized sheet that has passed the highest durability tests. The propellers are adjustable in angle and produced from special aluminum alloy material. The sound intensity is high due to the very high air velocity during operation, so there is a silencer on the suction and discharge sides of the product.

Detachable Slide System

Thanks to its special design, the engine can be easily accessed, the engine can be disassembled and reassembled. A sliding system was used in the design. All national and international certificates of the product are complete. All these features are produced on the basis of international standards.

Energy Saving with Automation System

Thanks to the integrated Fantürk Jet Fan Automation, it works fully equipped against all possible bad scenarios and prevents dangers in the area where it is used. It can evacuate smoke in the fastest way in case of fire. In addition, thanks to this automation, the fan provides significant energy savings by working according to the information coming from the sensors that measure the carbon monoxide rate in the environment.