Snail fans, also known as centrifugal fans or squirrel cage fans, are widely used in industrial ventilation systems to circulate air and remove contaminants from the air. In this article, we’ll explore what snail fans are, how they work, and the benefits they offer. We’ll also examine the different applications of snail fans in industrial ventilation.

What are Snail Fans?

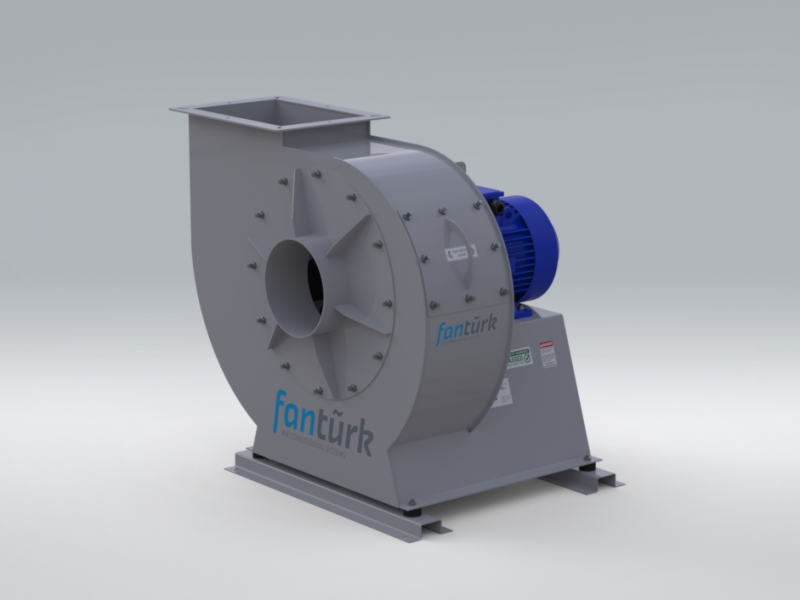

Snail fans are a type of centrifugal fan that consists of a cylindrical housing and a rotating impeller with curved blades. The blades draw air into the fan housing, which is then forced out in a radial direction by the centrifugal force created by the impeller. The air is then directed through ductwork to the desired location.

Snail fans are named for their distinctive shape, which resembles a snail’s shell or a squirrel cage. They are commonly used in industrial ventilation systems to circulate air and remove contaminants from the air.

How do Snail Fans Work?

Snail fans work by drawing air into the fan housing through the impeller blades, which are curved to direct the air in a radial direction. The centrifugal force created by the rotating impeller then forces the air out of the fan housing and into the ductwork system.

The direction of the airflow can be changed by adjusting the angle of the impeller blades or by using dampers in the ductwork system. This allows for precise control of the airflow and ensures that the air is directed to the desired location.

Benefits of Snail Fans

Snail fans offer a range of benefits, including:

Energy efficiency: Snail fans are designed to operate efficiently and consume less energy than other types of fans, making them an energy-efficient solution for industrial ventilation.

High airflow rates: Snail fans can achieve high airflow rates, making them suitable for use in large industrial spaces.

Low noise levels: Snail fans are designed to operate quietly, making them suitable for use in areas where noise levels need to be kept to a minimum.

Easy maintenance: Snail fans are easy to maintain and require minimal upkeep, reducing the overall cost of ownership.

Applications of Snail Fans

Snail fans are primarily used in industrial ventilation systems to circulate air and remove contaminants from the air. They are used in a wide range of applications, including:

Manufacturing facilities: fans are commonly used in manufacturing facilities to remove contaminants from the air and maintain a safe and healthy working environment.

Warehouses: Fans can be used in warehouses to circulate air and maintain a consistent temperature throughout the space.

HVAC systems: Fans can be integrated with HVAC systems to distribute conditioned air evenly throughout a building.

Clean rooms: Fans can be used in clean rooms to circulate air and remove contaminants from the air.

Choosing the Right Snail Fan

When selecting a snail fan, it’s important to consider factors such as the required airflow rate, the system pressure, and the space available for installation. It’s also important to choose a fan that is appropriately sized for the application to ensure maximum efficiency and performance.

Additionally, the material used in the construction of the fan is critical. The fan should be made of high-quality materials that can withstand the harsh conditions of industrial environments.

Conclusion

Snail fans are a crucial component of industrial ventilation systems, providing efficient and effective air circulation and contaminant removal. With their energy efficiency, high airflow rates, low noise levels, and ease of maintenance, fans are a popular choice for many industrial applications.

When selecting a snail fan, it’s important

to consider factors such as the required airflow rate, system pressure, and available installation space. Choosing the right fan and materials is essential to ensure maximum efficiency and performance.

With their ability to circulate air and remove contaminants from the air, fans play a critical role in maintaining a safe and healthy working environment in industrial settings. Their importance should not be underestimated, and industrial facility owners and managers should ensure that they are properly installed, maintained, and inspected to ensure maximum performance and safety.

Additionally, regular maintenance and inspection of fans is essential to ensure their continued operation and prevent unexpected breakdowns. This can include tasks such as cleaning the fan blades and housing, checking and tightening any loose connections, and inspecting the fan motor and bearings for wear and tear.

In conclusion, fans are an essential component of industrial ventilation systems, providing efficient and effective air circulation and contaminant removal. With their energy efficiency, high airflow rates, low noise levels, and ease of maintenance, fans are a popular choice for many industrial applications. Choosing the right fan and materials, as well as regular maintenance and inspection, are essential to ensure maximum efficiency and performance and maintain a safe and healthy working environment in industrial settings.