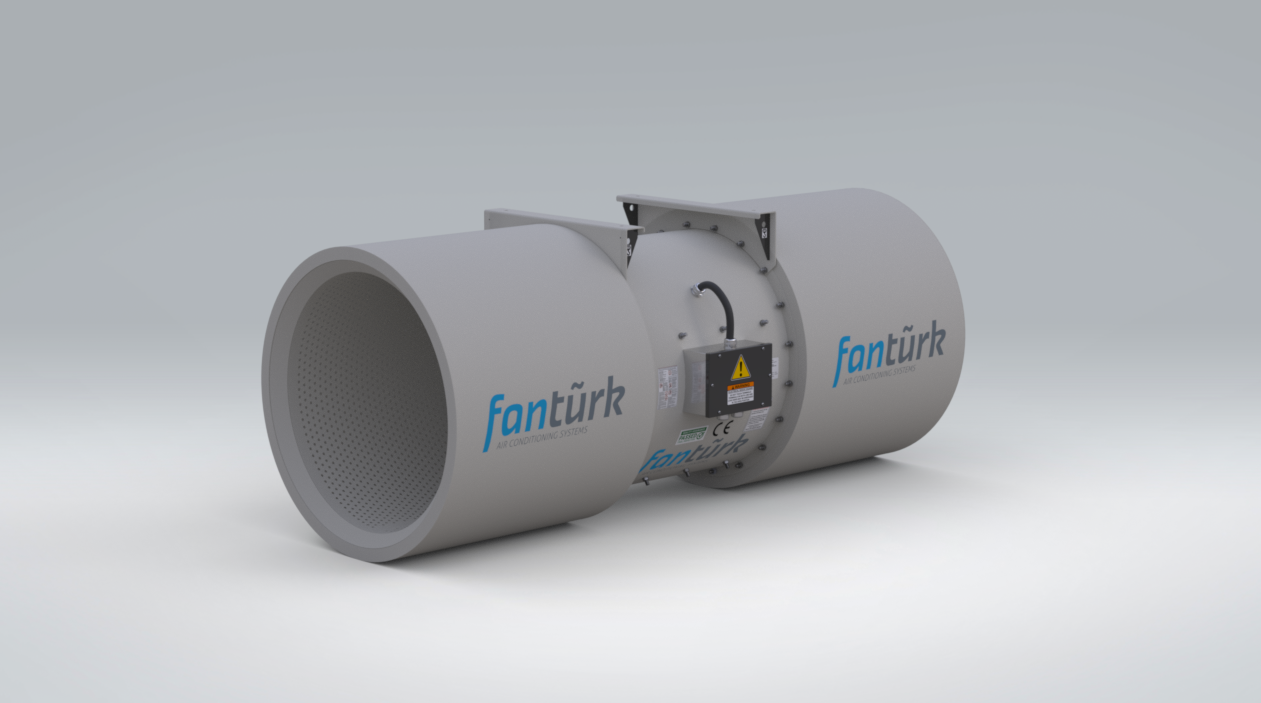

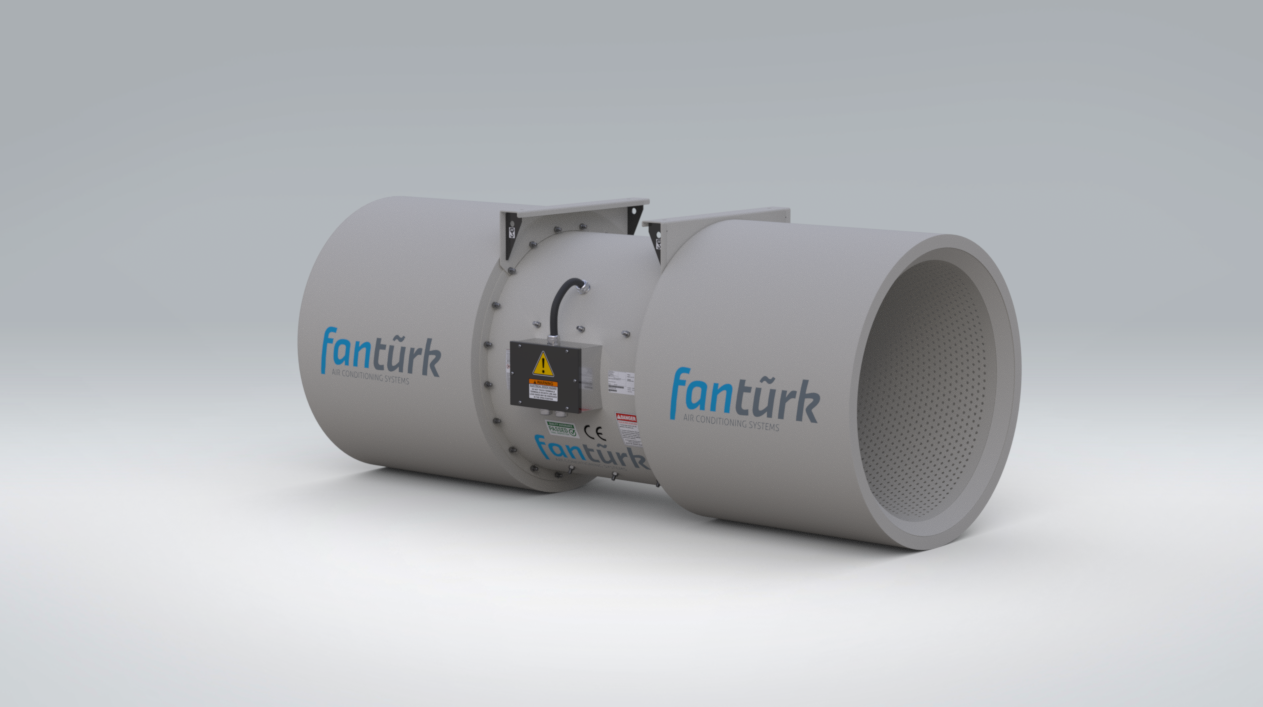

T-FWA Tunnel Jet Fan; The equipment of T-FWA Tunnel Jet Fan models are certified to EN 12101-3 fire resistant to 400 degrees for 2 hours and to 300 degrees for 2 hours by internationally recognized accreditation bodies. It is manufactured between Ø560 mm and Ø1600 mm diameters. According to the project used, there are two-way, one-way, double-speed and single-speed options. Especially the jet fan systems used in tunnels direct the air masses forward and create an artificial air flow inside the tunnel. It is used to prevent the accumulation of flammable and harmful gas in the tunnel on days when the air is stagnant outside the tunnel.

The main principle in the jet fan system is that the jet fans create momentum when necessary and direct the smoke to the exhausted openings (shafts). This system provides great advantages in the uniform distribution and exhaustion of clean air in the entire indoor area. This system consists of main exhaust fans, exhaust shafts, fresh air fans and fresh air shafts in multi-storey car parks, jet fans, CO detector system, smoke dampers, fresh air dampers, main control panels and other panels.

As it is known, tunnels can sometimes be far from settlements, in such cases the tunnel ventilation system must be connected to an automation system and operated. Thanks to the air quality sensors installed in the tunnel, the jet fans operate automatically when the air quality decreases. It can work without the need for human factor. Jet fans used in parking lots are designed for two different uses. The first duty of the parking jet fans is to direct the harmful gases emitted from the automobile exhausts to a certain exit point. Secondly, it is used to provide rapid evacuation of smoke and flame in case of a possible fire in the parking lot.

Parking lot jet fans are manufactured with two speeds. It operates at low speed during normal operating times. It works at high speed in case of fire in case of danger. The air thrust of the jet fans operating in the second cycle is up to 120 meters. With the air pushing system of the smoke evacuation fan, it provides fast transfer without force distribution. Heat resistant smoke engines are used in jet fans.

Car Park Jet Fans should provide at least 6 air changes of the total car park volume in daily operation. For smoke evacuation, at least 10 air changes of the single floor car park volume should be provided in an emergency. In a ventilation shaft, the total ventilation load should be divided 50% + 50% by two equivalent fans. The fans must be able to operate for a minimum of 300 C – 2 hours. Fresh air sources should be considered. If there is not enough natural fresh air intake, fresh air should be provided with the help of fans.

T-FWA Tunnel Jet Fan and Its Advantages

The Advantages of Jet Fan System are quite high. In general, the task of jet fans is to ensure that the air or smoke in the parking lot or tunnel volume is directed to the exhaust point in a controlled manner, thanks to the serious pressure reduction they will create at the ceiling level. In addition, with these systems;

- No need for duct assembly.

- No need for grilles and diffusers.

- Air flow is much faster and more efficient.

- Smoke control and zoning can be done.

- Floor heights can be reduced architecturally.

- It provides energy saving for the business.

- It provides easy revision opportunity during the project.

- Dead zones in ducted systems are eliminated.

- An elegant and spacious environment is provided in car parks and tunnels.

- Provides flexibility and ease of assembly.

- Provides easy commissioning.

T-FWA Tunnel Jet Fan Components

The equipment of T-FWA Tunnel Jet Fan models are certified to EN 12101-3 fire resistant to 400 degrees for 2 hours and to 300 degrees for 2 hours by internationally recognized accreditation bodies. It is manufactured between Ø560 mm and Ø1600 mm diameters. According to the project used, there are two-way, one-way, double-speed and single-speed options. The general components of the system are as follows;

1-Fan Body: The body of T-FWA Tunnel Jet Fan models is manufactured from high quality St52 quality sheet metal.

2-Propeller: The blade angles of the blades of the propellers used in T-FWA Tunnel Jet Fan Models are adjustable, the body and blades are made of special alloy aluminum. According to the project, it can operate with the same performance in both blowing directions, thanks to its reversible blade structure. It complies with international standards.

3-Electric Motor: It is manufactured as standard (380 V – 50 Hz) or for use in other voltages and frequencies (400 / 415/ 440 V – 50 Hz) upon request. As a standard, Class H, S1+S2, IP55 single-speed or double-speed motors are used, which can withstand 400 degrees for 2 hours or 300 degrees for 2 hours, depending on demand.

4-Other Components: In these series, the sound intensity increases due to high air outlet velocities and therefore, tunnel jet fans are used with silencer as standard.

Fantürk air conditioning

Our company has been operating in Bursa under the name of Havart Klima Ltd Şti and the brand name of Fantürk since 2002. In an area of 7000 m², it addresses the sector with the production of air conditioning devices, automation system software and MCC-DDC panel manufacturing with our engineers and blue-collar employees who are experts in their branches.

Fantürk is a company that produces technologies that give humanity a breather, aims to be a worldwide leader company and tries to offer innovative technologies for the benefit of humanity. In the light of our experience, our company, which is sensitive to customer expectations, prioritizes quality, and adopts respect for business ethics and ethical beliefs, has a vision that aims to develop and grow. Our principle is to have a discipline that is sensitive to customer expectations, attaches importance to quality, and respects ethical values.

In the light of our experience and knowledge, our company, which is sensitive to customer expectations, prioritizes quality, and adopts respect for business ethics and ethical beliefs, has a vision that aims to develop and grow. Attaching importance to R&D studies, Fantürk aims to increase its production and service quality based on international standards. Our main goal is to be a worldwide leader organization that produces technologies that breathe for all humanity by offering innovative technologies for the benefit of humanity

Our Service and Product Categories

Duct Type Fans, Roof Type Fans, Heat Recovery, Parking Lot Ventilation, Stair and Elevator Pressurization, Snail Fan, Cell Fans, Air Handling Unit, Dust Collection System, Hot Air Appliance

Our products

- Y-KTF Round Duct Type Fan

- D-KTF Rectangular Duct Type Fan with External Motor

- SHS Duct Type Shelter Ventilation Device

- ÇTF (230V) Single Phase Roof Type Radial Fan

- ÇTF (380V) Three Phase Horizontal Discharge Roof Type Radial Fan

- ÇTF (380V) Three Phase Vertical Discharge Roof Type Radial Fan

- Ç-FWA Roof Type Axial Fan

- IGK Ceiling Type Heat Recovery Device

- J-FWA Axial Jet Fan

- R-FWA Radial Jet Fan

- Y-FWA Axial Smoke Exhaust Fan

- P-FWA Axial Fresh Air Fan

- Car Park Ventilation System Automation Panel

- Pressurization System Automation Panel

- ABF Low Pressure Snail Fan

- OBF Medium Pressure Snail Fan

- ECO Series Forward Curved Closed Blade Cell Fan

- M-HA Metal Oil Filter Cell Kitchen Aspirator

- H-FWA Cell Axial Fans

- FKS Air Handling Unit

- HNS Pool Dehumidification Unit

- TT Dust Collection System

- R-APA Radial Fan Hot Air Appliance

- A-APA Axial Fan Hot Air Appliance

- FRTT Rooftop Roof Type Air Handling Unit

- T-FWA Tunnel Jet Fan

The products have fire-resistant certificate and tested for working for 2 hours at 400 °C in international accredited organizations according to EN 12101-3 standard. It is manufactured between Ø560mm and Ø1600mm diameters. According to the Project two-speed or single-speed options are available. Reversible propeller is standart.

Fan Body

T-FWA Axial Jet Fan models are manufactured from high quality S355 sheet.

Propeller

The propellers are made of special aluminum alloy with adjustable blade angles. According to the project, it can operate in the same performance in both blowing directions thanks to its reversible blade structure. Complies with international standards

Motor

It is manufactured as standard (380 V – 50 Hz) or other voltages and frequencies (400/415/440 V -50 Hz) on request. As a standard, Class H, S1, IP55 single-speed or double-speed motors with a resistance of 2 hours to 400 degrees are used.

Accessories

In this series, the sound volume increases due to the high air outlet velocities and therefore tunnel jet fans are used as standard with the silencer.