Air handling unit ensures that the air taken from the atmosphere is sent to the environment through certain processes. It is a system that provides fresh air flow to the environment, adjusting temperature and humidity rates, and purifying the air from dust and particles.

How Air Handling Unit Works?

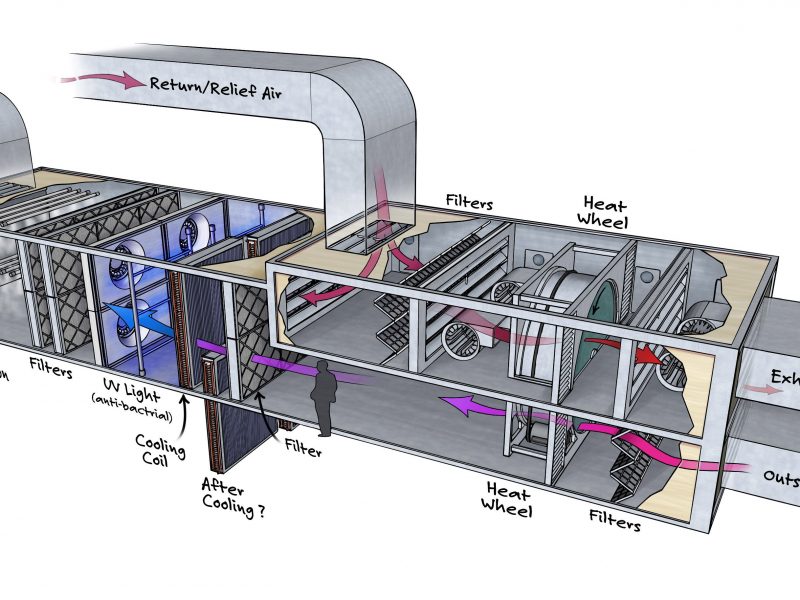

The operating principles of air handling units are different for each system. In general, all systems have damper motor, filter, heating and cooling coil, ventilator and aspirator. Parts other than these vary depending on the type of system.

The aspirator is responsible for taking air from outside. The ventilator, on the other hand, allows the air inside to be thrown out. In order for the air handling unit to operate, fresh air must be supplied through the dampers. The working principle varies according to the type of air unit. In general, it works by passing the fresh air through various sections and giving the desired air to the environment.

Parts of the air handling unit

Before having an air handling unit built, it is useful to know its technical and physical characteristics. It is possible to list the basic parts of this product, which consists of many parts, each of which has a different importance.

The section called the mixing chamber is the section that mixes the air of different values and converts it to the desired air in the final use. It is an energy-saving and multi-purpose piece.

Dust filters are filters used to clean the air. Hepa filter is divided into three as panel filter and bag filter.

Preheater and cooler sections gain great importance in winter and summer months. It plays a role in the regulation of the water used and the humidity released.

The humidifier section works to avoid excess or low humidity and to regulate the setting. Spray, water and steam humidification options are available according to needs.

The drip trap prevents the water escaping from the humidifier from mixing with the outlet air.

The after heater section helps to keep the specific humidity constant regardless of summer or winter. It has reflective, mute and absorber options.

Finally, the fan section, namely the ventilator and aspirators, are the sections that perform the operations of pushing or sucking the air. There are volute, direct flow and axial fans.

As long as all these models and sections are produced from durable materials, it is possible to have long-lasting quality They. Different functions and section qualities have an impact on the price list. This causes you to encounter products with a wide price range. Fanturk works for every budget with its wide price range. You can contact Fantürk for suitable for your budget.

Air Handling Unit Types

They are divided into types according to the purpose of use and the area to be used.

Mixed Air Handling Unit; It can mix the exhaust air with the desired amount of fresh air. When the exhaust air and the outside air reach the same oxygen level, it mixes the exhaust air with fresh air and reduces the fresh air damper. This system is not used in hospitals, pharmaceutical factories, kitchens and areas where the exhaust air is very polluted.

Heat Recovery Air Handling Unit; They are the systems that regulate the air by transferring their energies to each other in the heat recovery cell without mixing the fresh air with the exhaust air. Provides energy savings with efficiencies up to 70%.

Fresh Air Plant System; They are systems that transfer the air taken from the atmosphere to the environment. Exhaust process is provided with cellular aspirators.

Hygienic Air Handling Unit; It is used for ventilation of hygienic environments. The hygienic air handling unit, particles and microorganisms must not enter the system. Microorganisms should not be allowed to form. Attention should be paid to cleaning and maintenance. It is frequently used in areas such as indoor pool, SPA, operating room, pharmaceutical production facilities, laboratories, museums and food production facilities.

Comfort Air Handling Unit; It is suitable for meeting the need for fresh air in living spaces. Used as shelter ventilation, comfort conditioning units, pool dehumidification units.

Industrial Air Handling Unit; It is frequently used in paper production and usage facilities, textile production facilities, ceramic production facilities and petrochemical facilities. It is used to create suitable weather conditions for the products produced in the manufacturing industry. Air conditioning systems allow the implementation of chiller cooling projects.